Views: 0 Author: Site Editor Publish Time: 2025-11-29 Origin: Site

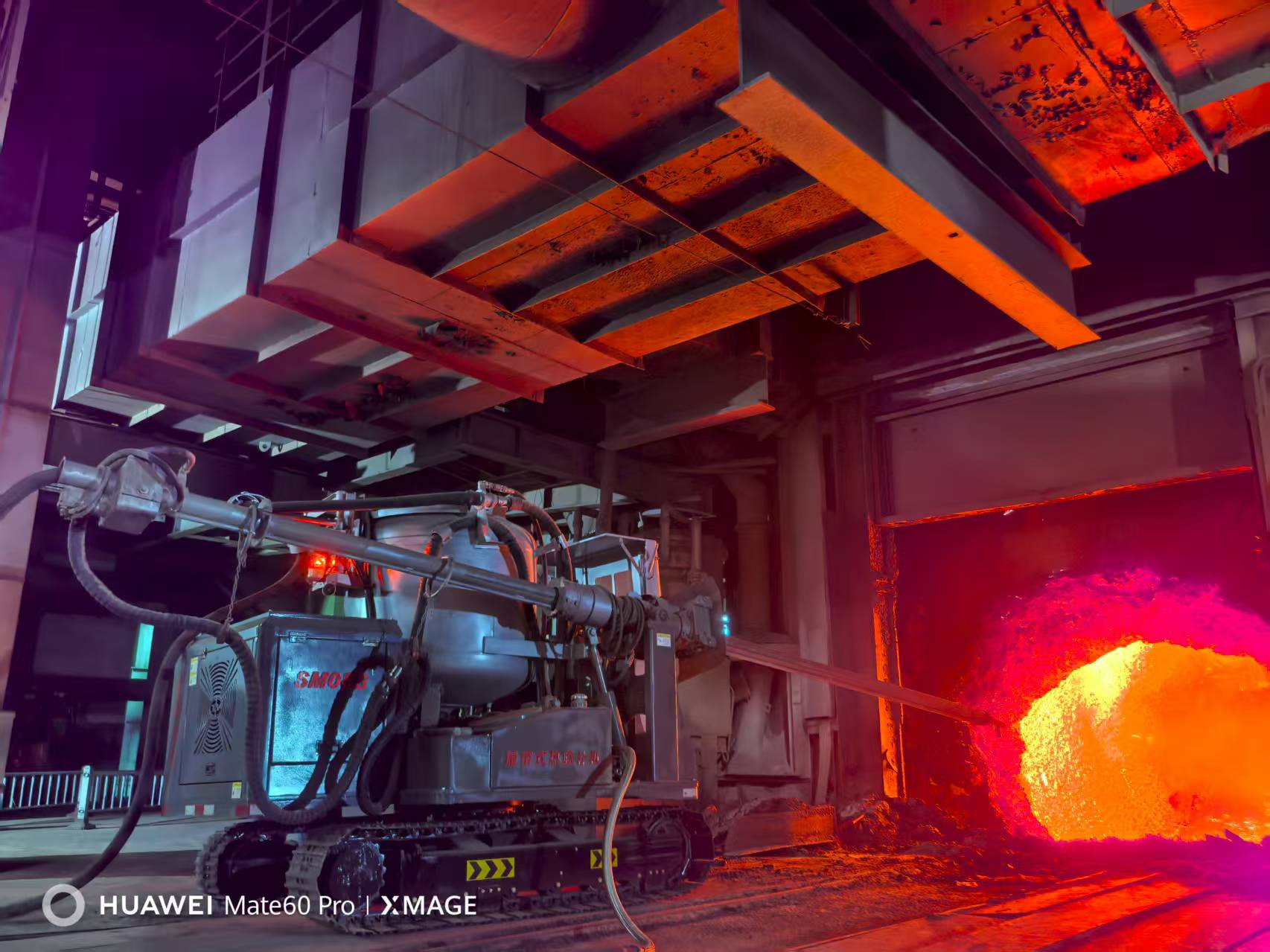

Full-Automatic Converter Gunning Machine - Repair Without Shutdown

I. Core Positioning of the Equipment: A Precision Repair Expert in High-Temperature Environments

In the iron and steel smelting industry, the lining of converters endures long-term scouring and erosion by molten steel at temperatures above 1200°C. Local melting loss directly affects production continuity and safety. Traditional furnace repair techniques require 60-90 minutes for sintering, with high maintenance costs and uneven results. The emergence of the SM08 crawler self-propelled hot patching machine has completely changed this situation. As a fully automatic equipment specifically designed for local repair of converter linings, it can respond quickly in extreme high-temperature environments of 1200°C, accurately locate melting loss areas and complete efficient repairs. This significantly shortens shutdown maintenance time and provides core support for iron and steel enterprises to reduce production costs and improve operational efficiency.

II. Vehicle Performance and Movements: Multi-Dimensional Control, Flexible and Efficient

The SM08 hot patching machine features comprehensive automatic operation capabilities and integrates multiple core movement functions to meet repair needs under complex working conditions:

All-terrain mobility: It adopts a crawler travel system, combined with hydraulic motor drive and travel reduction mechanism braking. This enables flexible vehicle movement and stable steering, easily adapting to the complex ground environment of steelmaking workshops and accurately reaching the operation position.

All-terrain mobility: It adopts a crawler travel system, combined with hydraulic motor drive and travel reduction mechanism braking. This enables flexible vehicle movement and stable steering, easily adapting to the complex ground environment of steelmaking workshops and accurately reaching the operation position.

Multi-dimensional adjustment and positioning: The upper platform supports 360° rotation at any angle within ±110°, and is matched with the telescopic, lifting and swinging mechanisms of the injection pipe. This ensures the nozzle coverage fully meets the repair needs of all areas of the converter lining. The total telescopic stroke of the injection pipe can reach 12m, allowing tilt adjustment of 12° upward and 20° downward to accurately align with melting loss parts for targeted repair.

Efficient material conveying: The patching material conveying device realizes stable feeding and uniform injection of patching materials through gas-liquid linkage control. Combined with the precise control of the injection pipe drive system, it ensures uniform thickness of the repair layer and firm bonding, effectively extending the converter service life.

III. Core Structure and Configuration: Stable, Reliable, Safe and Durable

The equipment adopts a modular design, and core systems are equipped with high-quality components, balancing performance stability and operational safety:

Power and hydraulic system: It uses a 36KW four-stroke diesel engine as the power source, matched with the Tianjin Bomco triple gear pump hydraulic system. The working pressure can reach 16MPa, providing strong and stable power output for the vehicle's movements. Hydraulic components and key mechanical parts all use high-quality industrial products to reduce equipment failure rate from the source.

Electrical control system: The operation console is equipped with a liquid crystal display monitor, which displays key working parameters such as engine speed and hydraulic pressure in real time. It also has an abnormal early warning function, providing accurate diagnosis basis for maintenance personnel and reducing maintenance shutdown time.

Safety protection design: The front shield of the operation platform has a built-in fiber heat insulation layer, and the observation window uses high-temperature resistant special glass. This effectively blocks high-temperature radiation and splashes, greatly improving the operator's working environment and ensuring operation safety.

Durability optimization: Hydraulic hoses are selected from well-known domestic brands such as Qingxiang, and are equipped with special hose joints. This fundamentally eliminates hidden dangers such as oil leakage and pipe explosion, reducing equipment maintenance frequency and maintenance costs.

IV. Overall Structural Composition: Modular Design, Complete Functions

The SM08 hot patching machine consists of six core systems, with each module working together to realize the full-process automatic patching operation:

Power unit: Provides stable power output to support the vehicle's operation and working movements.

Hydraulic system: Controls all movements such as travel, rotation and injection pipe adjustment to ensure stable operation.

Electrical control system: Realizes parameter monitoring, operation control and safety protection.

Injection pipe drive system: Precisely controls the telescoping, swinging and positioning of the injection pipe.

Patching material conveying device: Responsible for the storage, feeding and uniform injection of patching materials.

Crawler travel system: Ensures the equipment's movement and braking stability in complex environments.

V. Operation Experience: Flexible, Labor-Saving and High Adaptability

The equipment adopts a manual operation mode with a simple and intuitive control logic. Combined with the stable output of the hydraulic system, it achieves precise and controllable movements and flexible, labor-saving operation. Both experienced operators and novices can quickly get started to complete operations. At the same time, the overall structure of the equipment is compact, and its crawler design gives it good site adaptability. It can operate flexibly in the narrow space around the converter without complex site modification.

Conclusion

With its high-temperature operation capability, precise control performance and stable and reliable configuration, the SM08 crawler self-propelled hot patching machine has become an ideal equipment for converter lining maintenance. It not only solves the pain points of low efficiency and high cost of traditional furnace repair techniques, but also provides iron and steel enterprises with safe, efficient and economical repair solutions through automatic and intelligent design, helping enterprises improve production continuity and core competitiveness.

If you need it, I can help you sort out a bilingual comparison table of key technical terms in this text, which will make it easier for you to check and use professional vocabulary in both Chinese and English.