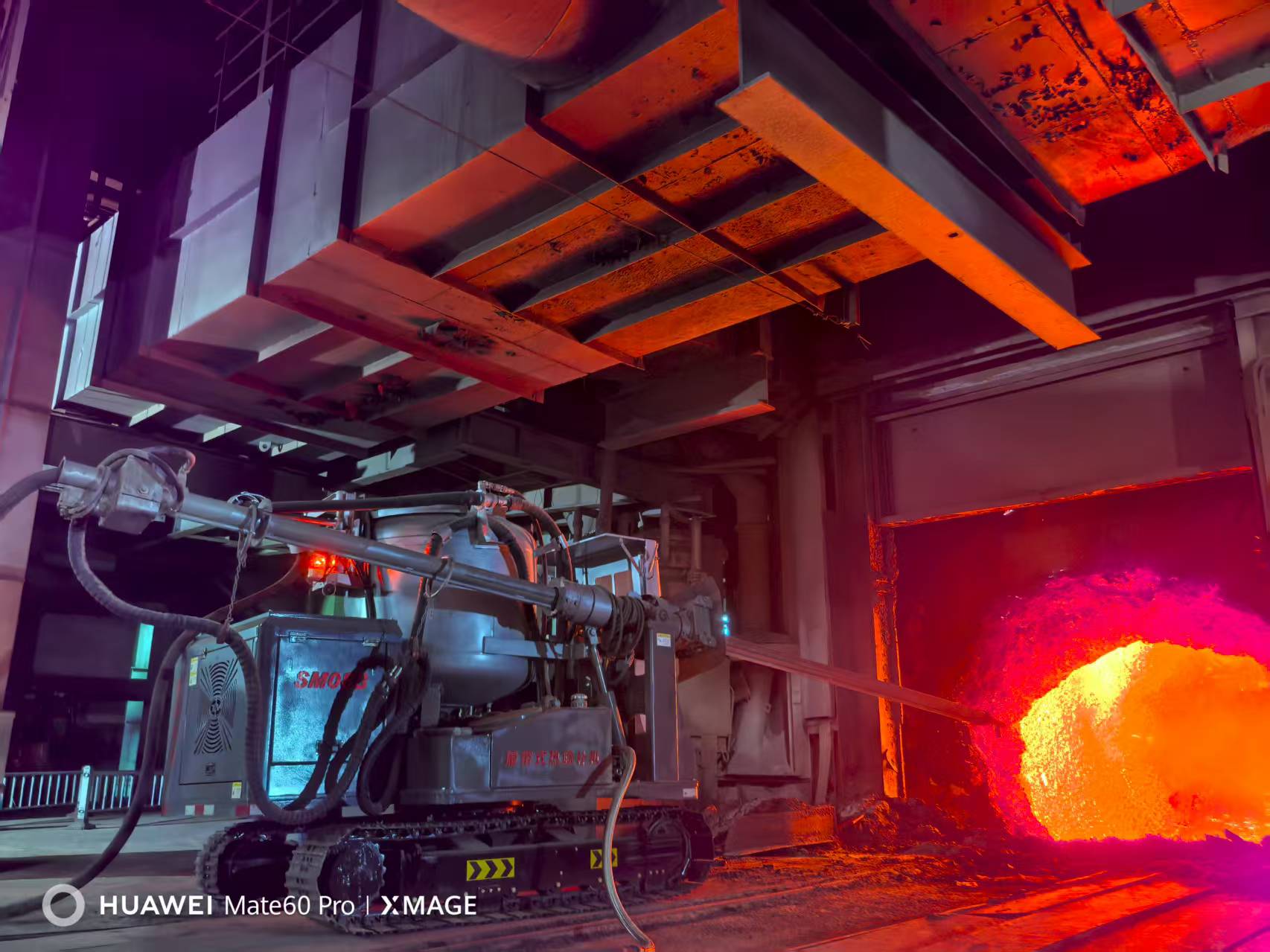

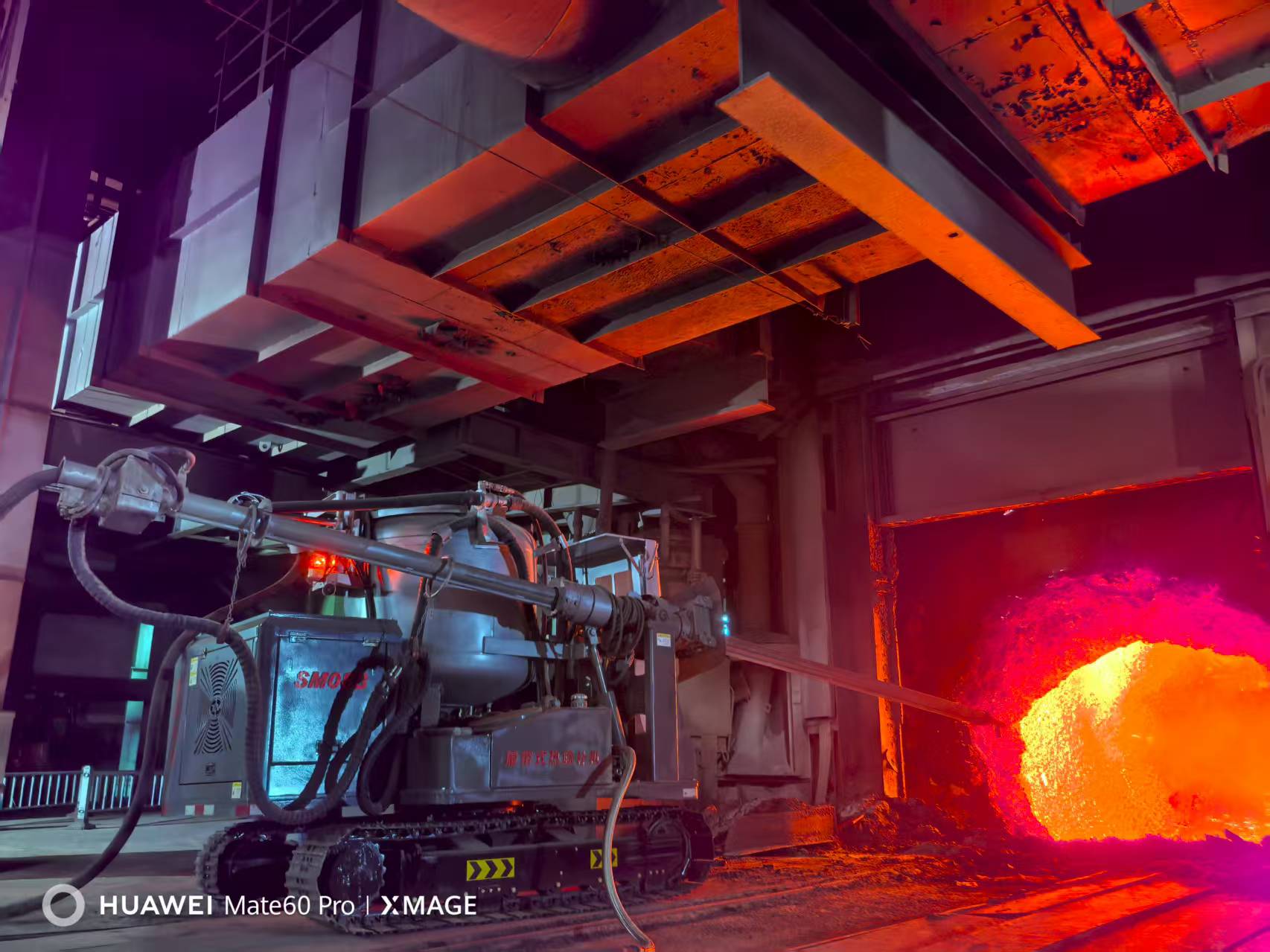

Innovake Converter Gunning Machine: Reshaping the New Paradigm of Maintenance for Iron and Steel Smelting Equipment

In the core link of iron and steel smelting, the converter is a key piece of equipment responsible for steelmaking tasks, and the integrity of its lining directly determines production efficiency, product quality, and operating costs. The long-term high-temperature and high-pressure smelting environment makes the converter lining highly prone to wear issues such as erosion and spalling. The traditional manual gunning maintenance method is not only inefficient and poor in safety but also struggling to ensure the stability of gunning quality, thus becoming a major bottleneck restricting the continuous production of iron and steel enterprises. Against this backdrop, the Innovic Converter Gunning Machine, with its technological innovation and practical applicability, provides a brand-new solution to the converter maintenance challenges in the iron and steel industry, promoting the transformation and upgrading of converter maintenance from "passive emergency repair" to "proactive and efficient".

I. Technological Breakthroughs: Building the Core Competitiveness of Efficient Gunning

The Innovic Converter Gunning Machine stands out due to its multiple breakthroughs in core technologies, covering gunning precision, material adaptability, and automated control, which comprehensively meet the strict requirements of modern iron and steel production for equipment maintenance.

In terms of precision gunning control technology, the equipment is equipped with a high-precision laser positioning system and an intelligent image recognition module. It can scan the surface of the converter lining in real time, quickly identify the position, area, and depth of eroded areas, and automatically generate a personalized gunning path. Compared with the traditional method where manual work relies on experience for judgment, this technology controls the gunning positioning error within ±5mm. While avoiding material waste, it ensures that the weak parts of the lining are accurately reinforced, effectively extending the service life of the lining.

In terms of material conveying and injection technology, the Innovic Converter Gunning Machine adopts a double-helix feeding structure and a high-pressure air injection system, realizing the uniform conveying and stable injection of gunning materials. The equipment is compatible with various types of gunning materials such as magnesia-carbon and alumina-magnesia. Moreover, it can automatically adjust the feeding speed and injection pressure according to the particle size and fluidity of the gunning materials, ensuring that the gunning layer has a uniform thickness and high compactness. Its bonding strength far exceeds the effect of manual gunning, greatly reducing the risk of secondary erosion of the lining.

In addition, the automated and intelligent control system of the equipment is a major highlight. Through the human-machine interface, operators can easily complete operations such as parameter setting, gunning monitoring, and fault diagnosis. The equipment also supports connection with the factory's MES system, realizing real-time upload and analysis of gunning data, providing data support for converter maintenance decisions, and truly achieving "unmanned operation and intelligent management".

II. Performance Advantages: Meeting the Practical Needs of Iron and Steel Production

In addition to innovations in core technologies, the performance advantages of the Innovic Converter Gunning Machine in practical applications are the key to winning the favor of iron and steel enterprises.

From the perspective of efficiency improvement, the traditional manual gunning of a 120-ton converter usually takes 4-6 hours, while the Innovic Converter Gunning Machine can complete all gunning operations in only 1.5-2 hours, with an efficiency increase of over 100%. This means that iron and steel enterprises can significantly shorten the converter maintenance time, increase the effective smelting duration, and create millions of yuan in additional economic benefits for the enterprise every year.

In terms of safety assurance, the equipment adopts a remote control mode. Operators do not need to enter the high-temperature and high-dust hazardous areas near the converter, completely avoiding safety risks such as scalding and dust inhalation that may occur during manual gunning, and providing a solid guarantee for the safe production of the enterprise. At the same time, the equipment is equipped with a complete set of safety protection devices, such as over-temperature alarms and pressure overload protection, further enhancing the safety and reliability of the equipment's operation.

In the aspect of cost control, the advantages of the Innovic Converter Gunning Machine are also significant. On the one hand, precise gunning control reduces the waste of gunning materials, increasing the utilization rate of gunning materials by more than 30%. On the other hand, the extension of the lining's service life (practice has proved that the service life of the converter lining can be extended by 20%-30% after using this equipment) reduces the frequency and cost of lining replacement. At the same time, it reduces the loss caused by production interruption due to lining problems, providing strong support for enterprises to achieve cost reduction and efficiency improvement.

III. Application Scenarios and Market Feedback: Empowering the High-Quality Development of the Iron and Steel Industry

With its outstanding performance, the Innovic Converter Gunning Machine has been widely used in different types of iron and steel production scenarios, such as large integrated iron and steel enterprises and special steel production enterprises. It is compatible with converters of various specifications ranging from 30 tons to 300 tons. Whether it is the conventional daily maintenance of converters or the emergency repair after severe local erosion of the lining, it can play an excellent role.

In the application case of a large domestic iron and steel group, after the enterprise introduced the Innovic Converter Gunning Machine, the converter maintenance time was shortened from the original 5 hours to 1.8 hours, and the lining service life was increased from the original 8,000 heats to 10,000 heats. The annual benefits from the saving of gunning materials and the improvement of production efficiency alone exceeded 5 million yuan. The person in charge of the enterprise said: "The Innovic Converter Gunning Machine not only solves the long-standing problems of low maintenance efficiency and high cost for us but also provides important support for the upgrading of our intelligent production. It is truly a 'production guarantee tool'."

In terms of market feedback, the Innovic Converter Gunning Machine has been recognized and purchased by dozens of domestic iron and steel enterprises, with its market share increasing year by year. At the same time, the equipment has passed international quality system certification and is gradually entering the international market. It has also achieved good application results in iron and steel enterprises in Southeast Asia, Central Asia, and other regions, becoming one of the representative products of China's iron and steel equipment technology "going global".

IV. Industry Significance and Future Outlook

The emergence of the Innovic Converter Gunning Machine not only solves the practical problems of converter maintenance for iron and steel enterprises but also holds great significance for the technological upgrading and green development of the iron and steel industry. Under the "dual carbon" goal, the iron and steel industry is facing severe challenges of energy conservation and emission reduction. By improving equipment maintenance efficiency and extending the service life of the lining, the Innovic Converter Gunning Machine reduces energy consumption and pollutant emissions during the start-up and shutdown of converters, which is in line with the industry's demand for green and low-carbon development.

In the future, Innovic will continue to focus on the technological needs of the iron and steel industry and continuously upgrade the converter gunning machine in the direction of "more intelligent, more efficient, and more environmentally friendly". For example, it will further optimize intelligent algorithms to improve the equipment's adaptability to complex lining working conditions; develop adaptation technologies for new environmentally friendly gunning materials and equipment to promote the greening of the gunning process; and explore a converter maintenance prediction system based on digital twin technology to achieve a leap from "on-demand gunning" to "predictive gunning", injecting more technological momentum into the high-quality development of the iron and steel industry.