Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

In the dynamic landscape of industrial demolition, the telescopic boom wrecking machine has emerged as a game - changing solution, particularly in the context of converter slag demolition and refractory brick demolition. This article delves into the capabilities of these machines, exploring their applications, advantages, and how they are transforming the efficiency and safety of industrial dismantling processes.

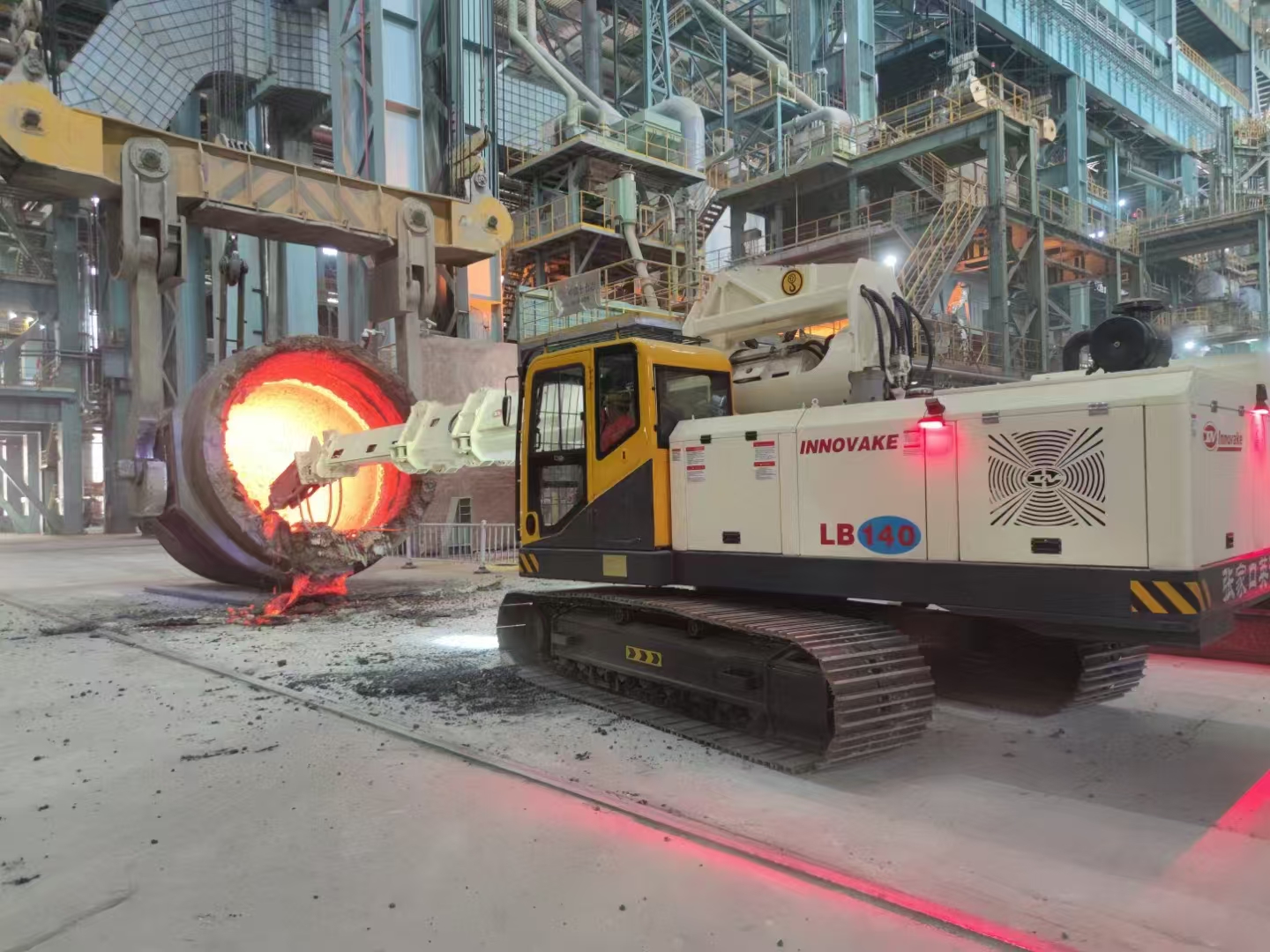

The process of converter slag demolition using a telescopic boom wrecking machine is as follows: First, the operator positions the machine near the converter. Using the remote - control or cabin - based controls, they extend the telescopic arm towards the slag - covered area. The hydraulic hammer or ripper attachment is then activated, delivering powerful blows to break up the slag. The broken pieces of slag can then be collected and removed for further processing or disposal.

Crawler - Mounted: Crawler - mounted telescopic boom wrecking machines are ideal for rough terrains and applications where stability is crucial. The crawler tracks distribute the machine's weight evenly, allowing it to operate on uneven surfaces without tipping over. This makes them suitable for use in industrial plants with unpaved areas or in situations where the machine needs to be positioned close to large structures. For example, in a steel - making plant where the ground may be littered with debris and uneven due to the nature of the operations, a crawler - mounted TBWM can move around with ease and maintain stability during the demolition process.

Tire - Mounted: Tire - mounted machines offer greater mobility and speed. They are well - suited for applications where the machine needs to be moved frequently between different work sites within an industrial complex. In a petrochemical plant with multiple furnaces and reactors that require refractory brick demolition at different times, a tire - mounted telescopic boom wrecking machine can be quickly driven to the location, saving valuable time.

Diesel Engine Drive: Diesel - powered telescopic boom wrecking machines provide high - power output and are suitable for applications where access to electrical power is limited. They are often used in remote industrial locations or in situations where continuous operation without interruption is required. For instance, in a mining operation where the power supply infrastructure may not be well - developed, a diesel - engine - driven TBWM can be relied upon to carry out converter slag demolition or other demolition tasks.

Electric Motor Drive: Electric - powered machines are more environmentally friendly and produce less noise and emissions. They are a popular choice for indoor applications or in areas where noise pollution and air quality are concerns. In a factory setting where workers are present in the vicinity of the demolition site, an electric - motor - driven telescopic boom wrecking machine can operate without disturbing the work environment.

Cabin - Operated: Cabin - operated machines provide the operator with a comfortable and protected working environment. The cabin is often equipped with air - conditioning and ergonomic controls, allowing for long - hours of operation without fatigue. In large - scale industrial demolition projects where the operator needs to be on - site for extended periods, a cabin - operated TBWM is a preferred choice.

Remote - Operated: Remote - control telescopic arm demolition machines offer enhanced safety, especially in hazardous environments. The operator can control the machine from a safe distance, away from potential dangers such as falling debris, high temperatures, or toxic fumes. This is particularly useful in applications like converter slag demolition, where the slag may release harmful gases during the demolition process. Some machines also offer the option of combined cabin and remote operation, providing maximum flexibility to the operator.

Enhanced Safety: By reducing the need for workers to be in close proximity to the demolition area, telescopic boom wrecking machines significantly improve safety. In converter slag demolition, the risk of workers being injured by flying slag fragments or inhaling harmful dust is minimized. In refractory brick demolition, the remote - control option ensures that operators are not exposed to the dangers of falling bricks or the harsh environment inside the furnace.

Increased Efficiency: The powerful attachments and flexible telescopic arms of these machines enable faster demolition. The ability to quickly change tools and reach difficult areas reduces the overall time required for the demolition process. For example, in a large - scale refractory brick demolition project in a cement kiln, a telescopic boom wrecking machine can complete the task in a fraction of the time it would take using traditional methods.

Precision Demolition: The precise control offered by these machines, especially in remote - controlled models, allows for targeted demolition. In refractory brick demolition, individual bricks can be removed without damaging the surrounding structure, which is essential for maintaining the integrity of the furnace or kiln for future repairs or renovations.

Reduced Maintenance: Many telescopic boom wrecking machines are designed with features such as protected hydraulic hoses and tool cylinders, as well as eccentric convex rollers for smooth travel. These features contribute to reduced maintenance requirements, ensuring that the machine remains operational for longer periods and minimizing downtime in industrial operations.