The metallurgy industry, as a cornerstone of modern manufacturing, relies heavily on a diverse array of tools and equipment to ensure the efficiency, precision, and safety of various production processes. Among these essential tools, the chisel rod stands out as a versatile and indispensable component, playing a pivotal role in tasks ranging from raw material processing to finished product refinement. This article delves into the characteristics, types, applications, key performance factors, maintenance strategies, and future trends of chisel rods in the metallurgy sector, highlighting their significance in driving industrial operations forward.

1. Definition and Core Functions of Chisel Rods in Metallurgy

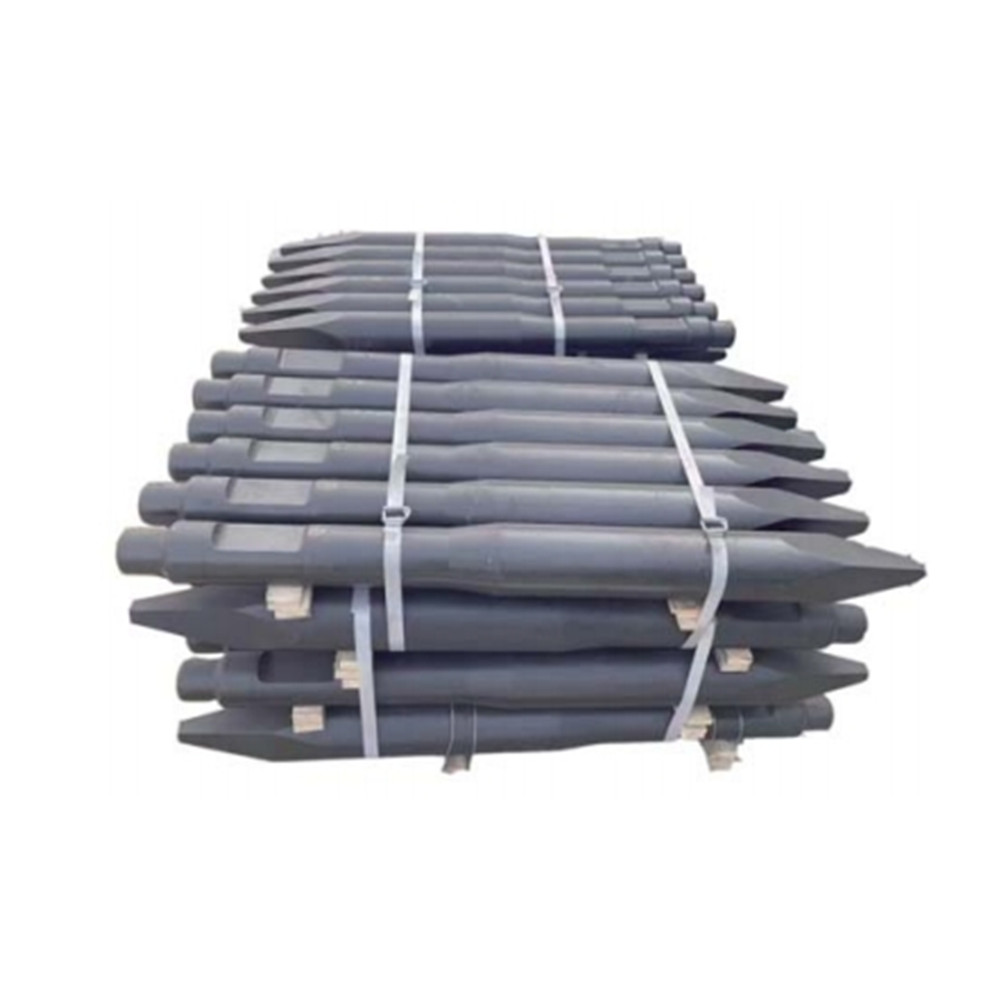

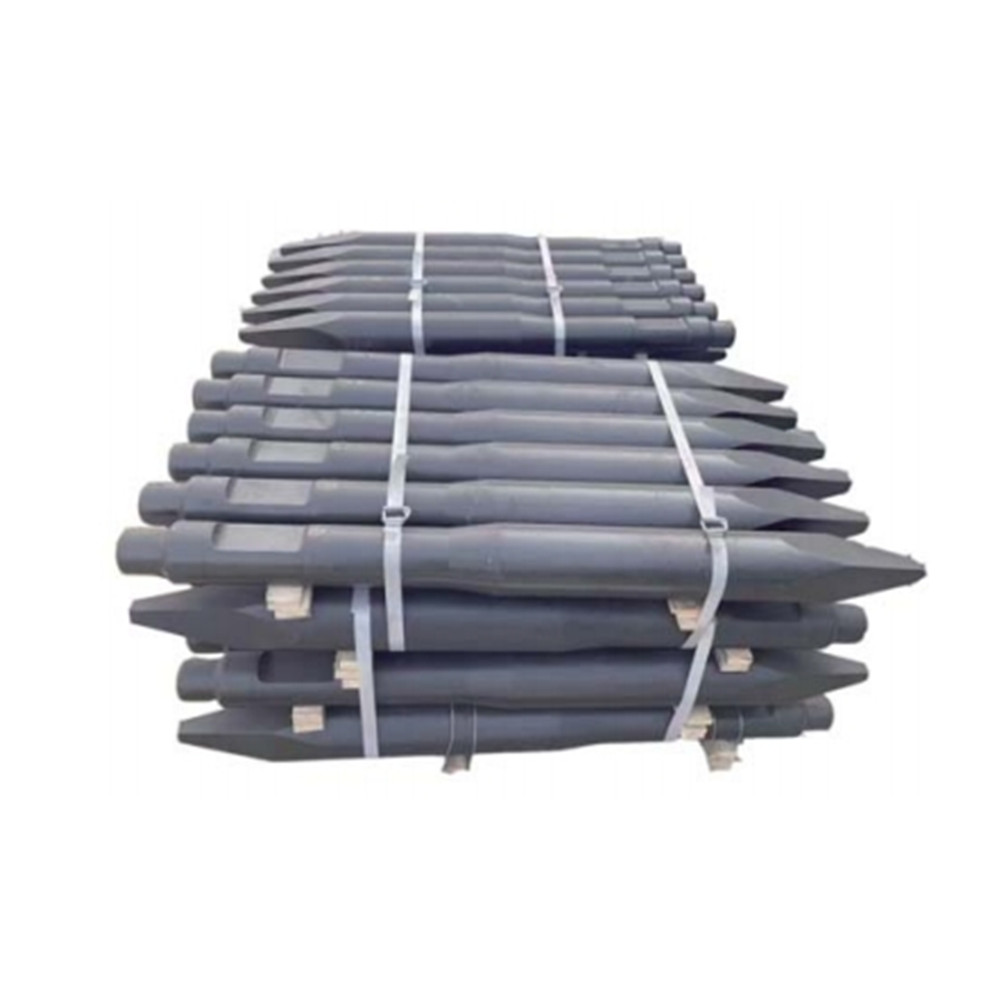

A chisel rod, in the context of metallurgy, refers to a solid, elongated tool typically crafted from high-strength materials. Its core structure consists of a sharpened working end (the chisel head) and a sturdy shank that facilitates handling or attachment to power tools. Unlike general-purpose chisels used in woodworking or construction, metallurgical chisel rods are engineered to withstand the extreme conditions inherent in metal processing—including high temperatures, intense impact forces, and abrasive environments.

The primary functions of chisel rods in metallurgy revolve around material shaping, removal, and precision adjustment. Specifically, they are designed to chip away excess metal, refine the surface of castings or forgings, split metal workpieces, and create precise grooves or notches. In many cases, chisel rods act as a "finishing touch" tool, ensuring that metal components meet the strict dimensional and surface quality requirements of downstream applications such as automotive, aerospace, and construction.

2. Main Types of Chisel Rods for Metallurgical Applications

The diversity of metallurgical processes has led to the development of various types of chisel rods, each tailored to specific tasks and operating conditions. The following are the most common categories:

2.1 Based on Material Composition

High-Speed Steel (HSS) Chisel Rods: These are widely used due to their excellent hardness, wear resistance, and heat resistance. HSS chisel rods can maintain their sharpness even when exposed to the moderate heat generated during metal chipping, making them suitable for processing medium-carbon steels and alloy steels. They are cost-effective and easy to regrind, making them a popular choice for small to medium-scale metallurgical workshops.

Cemented Carbide Chisel Rods: Composed of tungsten carbide particles bonded with cobalt, these chisel rods offer superior hardness and wear resistance compared to HSS. They can withstand high temperatures (up to 1,000°C) and intense impact, making them ideal for processing high-hardness metals such as stainless steel, titanium alloys, and cast iron. However, cemented carbide is relatively brittle, requiring careful handling to avoid breakage, and it is more expensive than HSS.

Tool Steel Chisel Rods: Made from high-carbon tool steel (e.g., A2, D2), these rods are known for their high toughness and durability. They are suitable for heavy-duty tasks such as splitting large metal ingots or removing thick layers of excess metal. Tool steel chisel rods are often heat-treated to enhance their hardness, balancing toughness and wear resistance for demanding metallurgical applications.

2.2 Based on Application Scenarios

Casting Chisel Rods: Designed specifically for processing cast metal components, these rods feature a slightly blunt chisel head to avoid damaging the internal structure of castings. They are used to remove casting defects such as flash, risers, and sand inclusions, ensuring the integrity of the final product.

forging Chisel Rods: Forging processes involve shaping metal under high pressure and temperature, and forging chisel rods are engineered to withstand these harsh conditions. They have a robust shank and a sharp, durable head for refining the shape of forged workpieces, such as gears, shafts, and connecting rods.

Precision Machining Chisel Rods: These are small-diameter chisel rods with ultra-precise sharpening, used for fine-tuning metal components to meet tight tolerances (often within 0.01mm). They are commonly used in the aerospace and automotive industries, where component precision directly affects product performance and safety.

3. Key Applications of Chisel Rods in the Metallurgy Process

Chisel rods are integrated into almost every stage of the metallurgy process, from raw material preparation to finished product inspection. Their specific applications include the following:

3.1 Raw Material Processing

In the initial stage of metallurgy, raw materials such as iron ore, copper ore, and aluminum ore are processed into metal ingots or billets. Chisel rods are used to split large ore blocks or ingots into smaller, more manageable sizes for subsequent smelting or rolling. For example, in steelmaking, tool steel chisel rods are used to split pig iron ingots into pieces that fit into smelting furnaces, ensuring uniform heating and melting.

3.2 Casting and Forging Refinement

Casting and forging are critical processes for shaping metal into complex components. After casting, chisel rods (typically casting-specific types) remove excess material such as flash and risers, which are unavoidable byproducts of the casting process. In forging, forging chisel rods refine the surface of workpieces, removing scale (oxide layers formed during heating) and adjusting the shape to meet design specifications. For instance, in the production of automotive crankshafts, forging chisel rods are used to smooth the surface of the forged blank, reducing the workload of subsequent machining.

3.3 Welding and Fabrication

In metal welding and fabrication, chisel rods play a key role in post-weld cleaning and shaping. They are used to chip away welding slag, remove excess weld metal, and smooth the weld bead, ensuring the weld joint is strong and aesthetically pleasing. For example, in the fabrication of steel structures (e.g., bridges, buildings), cemented carbide chisel rods are used to clean welds on high-strength steel, as they can withstand the hardness of the weld metal and avoid premature wear.

3.4 Defect Repair and Maintenance

Metallurgical components often develop defects such as cracks, dents, or surface blemishes during production or use. Chisel rods are used to repair these defects by removing damaged material and preparing the surface for welding or reprocessing. For example, in the maintenance of industrial machinery (e.g., rolling mills, smelting furnaces), precision machining chisel rods are used to repair small cracks on metal parts, extending the service life of the equipment.

4. Critical Performance Factors of Chisel Rods in Metallurgy

The performance of chisel rods directly affects the efficiency and quality of metallurgical processes. Several key factors determine their effectiveness in industrial applications:

4.1 Hardness and Wear Resistance

Hardness is the primary indicator of a chisel rod’s ability to withstand wear and deformation. For processing high-hardness metals, chisel rods with high hardness (e.g., cemented carbide) are required to avoid blunting or chipping. Wear resistance ensures that the chisel rod maintains its sharpness over extended use, reducing the frequency of tool replacement and improving production efficiency.

4.2 Toughness and Impact Resistance

Metallurgical tasks such as chipping and splitting generate intense impact forces. Chisel rods must have sufficient toughness to absorb these impacts without breaking. For example, tool steel chisel rods, with their high toughness, are preferred for heavy-duty impact tasks, while cemented carbide rods (which are brittle) are used for lighter, more precise applications where impact is minimal.

4.3 Heat Resistance

Many metallurgical processes involve high temperatures, and chisel rods can absorb heat from the workpiece during use. Heat-resistant chisel rods (e.g., HSS, cemented carbide) can maintain their mechanical properties at high temperatures, avoiding softening or deformation. This is particularly important in forging and welding applications, where workpiece temperatures can exceed 800°C.

4.4 Dimensional Precision

For precision machining applications, the dimensional accuracy of the chisel rod (e.g., diameter, length, chisel head angle) is critical. A precisely manufactured chisel rod ensures that the processed component meets tight tolerances, reducing the need for rework and improving product quality. For example, aerospace components require chisel rods with dimensional errors of less than 0.005mm to ensure safety and performance.

5. Maintenance and Care Strategies for Chisel Rods

Proper maintenance of chisel rods is essential to extend their service life, reduce operational costs, and ensure consistent performance. The following are key maintenance practices:

5.1 Regular Sharpening

Blunt chisel rods require more force to use, increasing the risk of operator fatigue and workpiece damage. HSS and tool steel chisel rods should be sharpened regularly using grinding machines, ensuring the chisel head maintains a consistent angle (typically 30–45° for metallurgical applications). Cemented carbide rods, due to their high hardness, require specialized diamond grinding tools for sharpening.

5.2 Proper Storage

Chisel rods should be stored in a dry, clean environment to avoid rust and contamination. They should be placed in dedicated tool racks or cases, with the chisel heads protected by caps to prevent damage. For long-term storage, chisel rods can be coated with anti-rust oil to prevent corrosion.

5.3 Rational Use and Load Control

Using the correct type of chisel rod for the task is critical. For example, avoiding using cemented carbide rods for heavy impact tasks can prevent breakage. Additionally, operators should control the force applied during use, avoiding excessive pressure that can deform or damage the rod. Using power tools (e.g., pneumatic chisels) with adjustable force settings can help maintain consistent load levels.

5.4 Regular Inspection

Before use, chisel rods should be inspected for cracks, chips, or deformation. Damaged rods should be repaired or replaced immediately to avoid safety hazards and workpiece defects. After use, rods should be cleaned to remove metal shavings and debris, which can cause wear during storage.

6. Future Trends of Chisel Rods in the Metallurgy Industry

As the metallurgy industry moves toward automation, digitization, and high-performance materials, chisel rods are also evolving to meet new demands. The following are key future trends:

6.1 Advanced Material Development

Research and development of new chisel rod materials are focused on balancing hardness, toughness, and heat resistance. For example, composite materials such as ceramic-reinforced cemented carbide are being developed to improve wear resistance while reducing brittleness. Additionally, nanocoating technologies (e.g., titanium nitride coatings) are being applied to chisel rods to enhance surface hardness and reduce friction, extending service life by up to 50%.

6.2 Integration with Automation

The rise of automated metallurgical production lines (e.g., robotic forging, automated casting) has led to the development of chisel rods compatible with robotic systems. These rods feature standardized shanks for easy attachment to robotic arms and are designed to work with sensors that monitor tool wear, enabling automatic tool replacement and reducing downtime.

6.3 Customization for Specialized Applications

With the growing demand for high-performance metals (e.g., lightweight alloys for electric vehicles, high-temperature alloys for aerospace), chisel rods are being customized for specific materials and processes. For example, chisel rods designed for titanium alloy processing feature a unique chisel head geometry to avoid material work hardening, while those for high-temperature alloy forging are made from heat-resistant superalloys.

6.4 Environmental Sustainability

The metallurgy industry is increasingly focused on sustainability, and chisel rod manufacturers are responding by developing eco-friendly products. For example, recycled high-speed steel is being used to produce chisel rods, reducing raw material consumption. Additionally, low-toxicity coatings and lubricants are being adopted to minimize environmental impact during production and use.

7. Conclusion

Chisel rods are an essential tool in the metallurgy industry, playing a critical role in raw material processing, component refinement, and defect repair. Their performance is determined by key factors such as material composition, hardness, toughness, and dimensional precision, and proper maintenance is essential to ensure optimal performance and longevity. As the metallurgy industry evolves, chisel rods are adapting through advanced material development, integration with automation, and customization for specialized applications, ensuring they remain a vital component of modern metallurgical operations. By understanding the characteristics and trends of chisel rods, metallurgical enterprises can select and use these tools more effectively, driving efficiency, quality, and sustainability in their production processes.

Chisel Rod in the Metallurgy Industry: A Comprehensive Overview

Chisel Rod in the Metallurgy Industry: A Comprehensive Overview