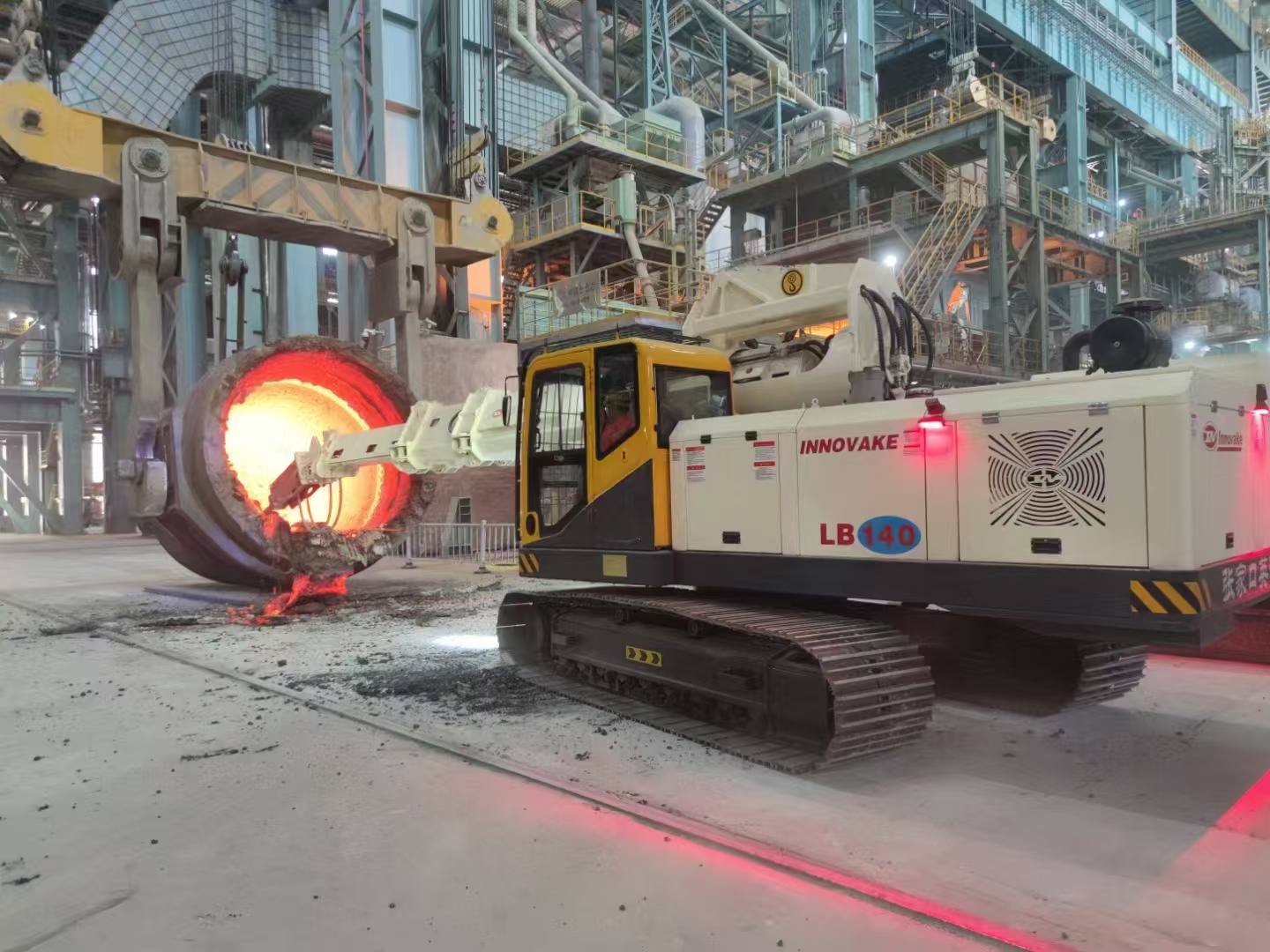

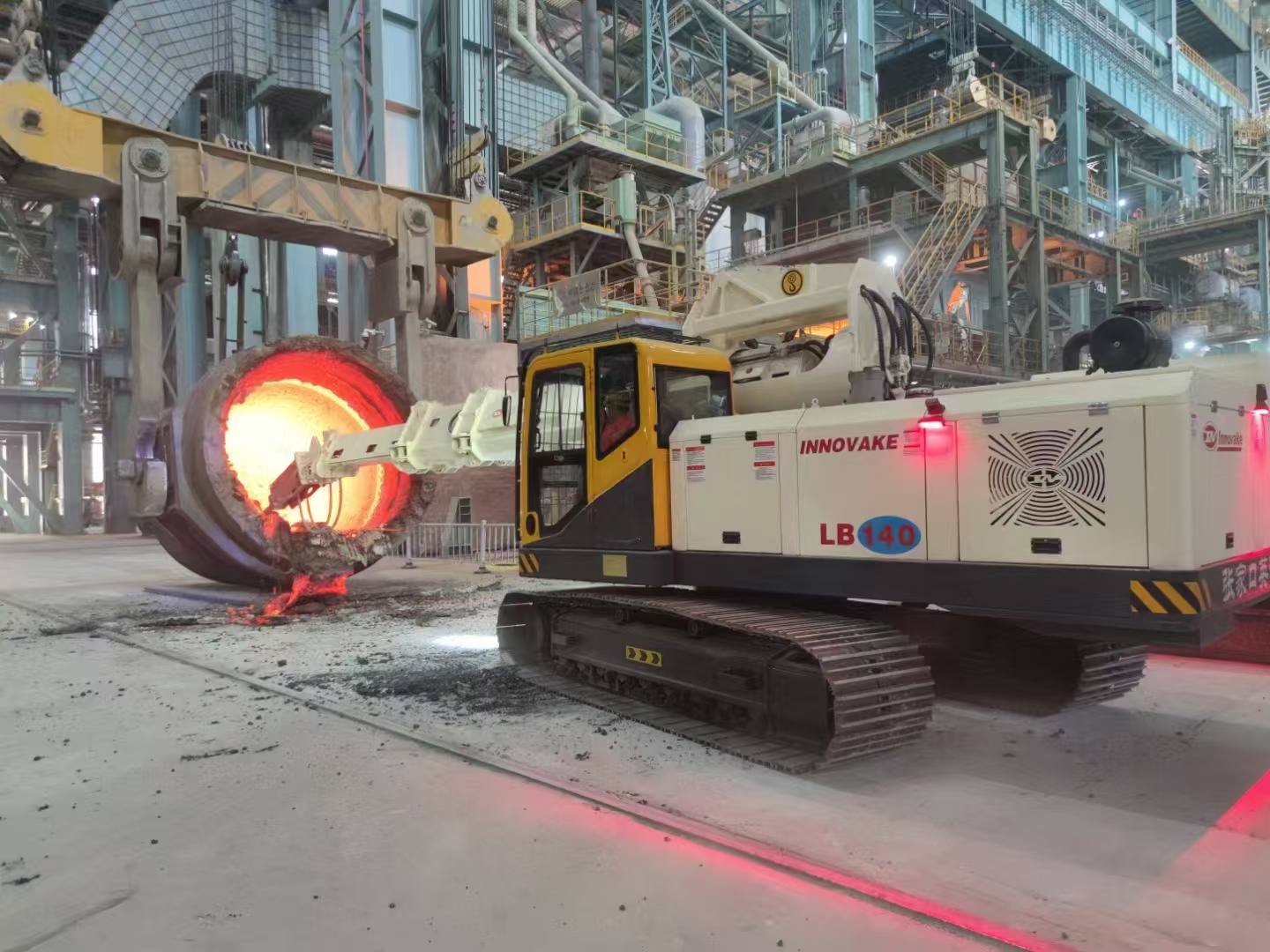

Converter/Ladle Blast Furnace Debricking Machine: A Critical Equipment for Iron and Steel Industry Efficiency

The iron and steel industry stands as the cornerstone of global industrialization, with blast furnaces, converters, and ladles serving as core equipment in the smelting process. However, during long-term high-temperature smelting operations, molten slag and metal oxides tend to adhere to the inner linings of these vessels, forming hard, dense deposits known as "scabs" or "clogs." These deposits not only reduce the effective volume of the equipment, lowering production capacity, but also pose severe risks such as uneven heat transfer, lining erosion acceleration, and even equipment explosion in extreme cases. Against this backdrop, the Converter/Ladle Blast Furnace Debricking Machine emerges as a pivotal solution, dedicated to removing these stubborn deposits efficiently and safely, thereby ensuring the stable and economical operation of smelting equipment.

1. Technical Principles: The Mechanism of Efficient Debricking

The debricking machine operates on the principle of combining mechanical impact, vibration, and targeted force application to break and remove deposits without damaging the equipment's inner lining. Unlike traditional manual debricking methods that rely on sledgehammers or simple pneumatic tools, modern debricking machines integrate advanced mechanical design and intelligent control systems to achieve precise and efficient cleaning.

For blast furnaces, the debricking machine typically accesses the furnace through the taphole or manhole. Its core working component—usually a high-strength impact hammer or rotating drill bit—extends into the furnace and adjusts its position and angle via a multi-degree-of-freedom mechanical arm. The impact hammer delivers high-frequency, low-amplitude vibrations or instantaneous high-impact force to the scabs, causing them to crack and fall off due to fatigue and stress concentration. For converters and ladles, which have smaller volumes and more complex inner structures, the debricking machine often adopts a flexible positioning system. It can adapt to the curved inner walls of the vessels, ensuring that the cleaning tool contacts the deposits evenly and avoids direct collision with the refractory lining.

In addition, many advanced debricking machines are equipped with temperature and thickness detection sensors. These sensors monitor the temperature of the inner lining and the thickness of the deposits in real-time, transmitting data to the central control system. The system then automatically adjusts the impact force, vibration frequency, and working path of the cleaning tool, realizing "on-demand debricking" and minimizing energy consumption and lining damage.

2. Core Components: The Backbone of Reliable Operation

A high-performance Converter/Ladle Blast Furnace Debricking Machine is composed of several key components, each playing a crucial role in ensuring its stability, efficiency, and safety. These components are designed to withstand the harsh working environment of high temperature, dust, and strong impact in the smelting site.

2.1 Mechanical Arm System

The mechanical arm is the "hand" of the debricking machine, responsible for positioning the cleaning tool accurately. It is usually made of high-strength alloy steel with good heat resistance and fatigue resistance. The multi-joint design allows the arm to achieve a large working range and flexible movement, enabling it to reach all areas of the equipment's inner lining. The joint parts are equipped with high-precision hydraulic or electric actuators, which provide stable power and precise control, ensuring that the cleaning tool can maintain a constant pressure and angle when contacting the deposits.

2.2 Cleaning Tool Assembly

The cleaning tool is the "teeth" of the debricking machine, directly interacting with the stubborn deposits. According to the type of equipment and the characteristics of the deposits, different types of tools are available, such as impact hammers, drill bits, and scrapers. The impact hammer is suitable for breaking large and hard scabs; its hammer head is made of wear-resistant materials such as tungsten carbide, which can withstand repeated high-impact collisions. The drill bit is used for removing deposits in narrow gaps or dead corners, while the scraper is suitable for cleaning relatively loose deposits on the surface of the lining. Many tools are designed with a quick-change structure, allowing operators to replace them quickly according to different working conditions, improving work efficiency.

2.3 Power and Control System

The power system of the debricking machine mainly includes hydraulic pumps, motors, and air compressors, providing power for the movement of the mechanical arm and the operation of the cleaning tool. The hydraulic system is widely used due to its high power density and stable output, which can meet the requirements of high-impact and heavy-load operations. The control system is the "brain" of the machine, consisting of a PLC (Programmable Logic Controller), touch screen, and remote control module. The PLC stores preset debricking programs for different equipment types and deposit conditions, and operators can start automatic debricking with one click. The touch screen allows real-time monitoring of the machine's working status, such as the position of the mechanical arm, the impact force of the tool, and the temperature of the lining. The remote control module enables operators to control the machine from a safe distance, avoiding the risk of injury from high temperature and flying debris.

2.4 Safety Protection System

Safety is a top priority in the smelting site, and the debricking machine is equipped with a comprehensive safety protection system. This includes emergency stop buttons, overload protectors, and temperature alarms. When the machine encounters an abnormal situation such as overload or excessive lining temperature, the system will immediately stop the operation and issue an alarm to remind operators to handle it. In addition, the machine's body is equipped with a heat insulation and dustproof cover, which not only protects the internal components from high-temperature radiation and dust erosion but also reduces noise pollution during operation.

3. Application Advantages: Transforming the Debricking Process

Compared with traditional manual debricking and simple mechanical cleaning methods, the Converter/Ladle Blast Furnace Debricking Machine has significant advantages in efficiency, safety, and economy, bringing substantial benefits to iron and steel enterprises.

3.1 Dramatically Improved Debricking Efficiency

Manual debricking is labor-intensive and time-consuming. A team of several workers may take 2-3 days to clean a single blast furnace. In contrast, a modern debricking machine can complete the same work in 8-12 hours, with a cleaning efficiency increased by more than 5 times. The automatic operation of the machine avoids the fatigue caused by manual work and ensures a stable cleaning speed and quality. Moreover, the machine can work continuously for a long time, further shortening the downtime of smelting equipment and improving the overall production capacity of the enterprise.

3.2 Enhanced Operational Safety

Manual debricking requires workers to approach the high-temperature smelting equipment, facing risks such as high-temperature burns, flying debris injury, and gas poisoning. The debricking machine realizes remote automatic operation, and operators only need to monitor the equipment's working status in the control room, completely avoiding direct contact with dangerous working environments. The safety protection system of the machine can also quickly respond to abnormal situations, preventing accidents such as equipment damage and personal injury.

3.3 Reduced Lining Damage and Extended Equipment Life

Traditional manual cleaning methods are difficult to control the force and angle, often causing excessive impact on the refractory lining of the equipment, accelerating lining erosion, and increasing maintenance costs. The debricking machine uses intelligent control and precise positioning technology to adjust the cleaning force and path according to the thickness of the deposits and the condition of the lining, ensuring that only the deposits are removed without damaging the lining. This can extend the service life of the refractory lining by 20%-30%, reducing the frequency of lining replacement and saving maintenance costs for enterprises.

3.4 Improved Smelting Quality and Reduced Energy Consumption

The presence of deposits in smelting equipment will affect the heat transfer efficiency and the uniformity of molten metal mixing, leading to unstable smelting quality and increased energy consumption. The debricking machine can thoroughly remove the deposits, ensuring the effective volume of the equipment and the normal heat transfer. This can not only improve the quality of steel products and reduce the scrap rate but also reduce fuel consumption by 5%-10% per unit of product, achieving energy saving and emission reduction.

4. Industry Development Trends: Towards Intelligence and Customization

With the continuous development of the iron and steel industry towards low-carbonization, intelligence, and high efficiency, the Converter/Ladle Blast Furnace Debricking Machine is also undergoing technological upgrades and structural optimization. The future development trends of the equipment are mainly reflected in the following aspects:

4.1 Higher Intelligence Level

The integration of artificial intelligence (AI) and big data technology will become the key direction of debricking machine development. In the future, debricking machines will be able to learn and optimize debricking strategies through big data analysis of historical working data, such as the type of deposits, the service life of the lining, and the smelting parameters. AI algorithms can automatically identify the location and thickness of deposits through image recognition technology, and formulate the optimal cleaning plan in real-time, realizing "self-adaptive debricking." At the same time, the equipment will be connected to the enterprise's MES (Manufacturing Execution System), realizing data sharing and coordinated operation with other smelting equipment, improving the overall intelligence level of the production line.

4.2 Customized Design for Different Scenarios

Different types of smelting equipment (blast furnaces, converters, ladles) and different smelting processes (pig iron smelting, steelmaking, refining) have different requirements for debricking machines. In the future, manufacturers will provide customized debricking solutions according to the specific needs of enterprises. For example, for large blast furnaces with complex inner structures, debricking machines with longer mechanical arms and more flexible positioning systems will be designed; for ladles with frequent use and short downtime, high-speed and efficient debricking machines with quick-change tool systems will be developed. Customized design can better meet the actual needs of enterprises, improving the applicability and efficiency of the equipment.

4.3 Low-Carbon and Energy-Saving Upgrades

In response to the global low-carbon development strategy, debricking machines will adopt more energy-saving power systems and materials. For example, the use of high-efficiency permanent magnet motors instead of traditional motors can reduce energy consumption by 15%-20%; the adoption of lightweight and high-strength materials for the mechanical arm can reduce the overall weight of the equipment, lowering power consumption during movement. At the same time, the waste heat recovery system will be integrated into the equipment to recover the high-temperature waste heat generated during the debricking process and convert it into electricity or heat energy for reuse, further improving energy utilization efficiency.

4.4 Enhanced Reliability and Maintenance Convenience

Manufacturers will further optimize the structure of the debricking machine, using more wear-resistant, high-temperature-resistant, and corrosion-resistant materials to improve the reliability and service life of the equipment. At the same time, the equipment will be designed with a modular structure, making the replacement of components more convenient and reducing maintenance time. The predictive maintenance system based on IoT (Internet of Things) technology will also be widely used. Sensors installed on key components of the machine can monitor the wear status and operating parameters of the components in real-time, predicting potential faults in advance and reminding operators to perform maintenance, avoiding sudden equipment failures and reducing production losses.

5. Conclusion

As a key equipment for ensuring the stable operation of smelting equipment in the iron and steel industry, the Converter/Ladle Blast Furnace Debricking Machine has irreplaceable advantages in improving production efficiency, ensuring operational safety, reducing maintenance costs, and improving smelting quality. With the continuous advancement of intelligent technology and the increasing demand for low-carbon development in the industry, the debricking machine will continue to undergo technological innovations, moving towards higher intelligence, stronger customization, and better energy-saving performance. In the future, it will play a more important role in promoting the high-quality development of the iron and steel industry, helping enterprises achieve cost reduction, efficiency increase, and green development.