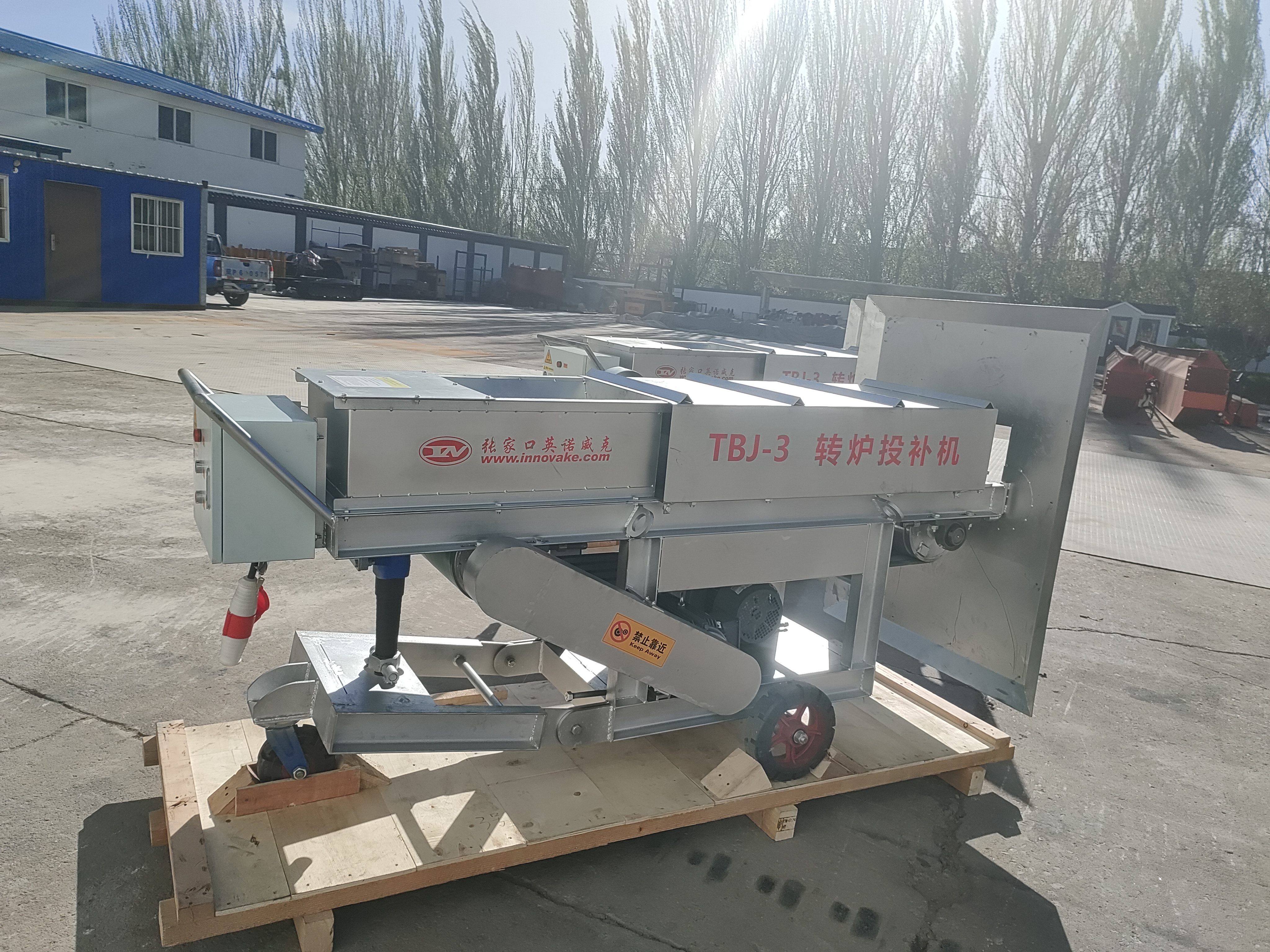

Converter Refractory Material Throwing Machine

1. Introduction

In the steelmaking process, converters play a crucial role. The working environment of converters is extremely harsh, with high temperatures, strong corrosion, and intense mechanical impacts. Therefore, the selection and maintenance of refractory materials are of great significance for ensuring the normal operation and service life of converters. The converter refractory material throwing machine has emerged as an important device to meet the needs of efficiently and accurately applying refractory materials in this context.

2. Working Principle of the Throwing Machine

2.1 Material Feeding System

The throwing machine is equipped with a sophisticated material feeding system. Usually, it consists of a hopper, a feeder, and related conveying devices. The hopper is designed to store a large amount of refractory materials. The feeder, which can be a screw feeder, vibrating feeder, or other types, controls the amount and speed of material feeding precisely. By adjusting the rotation speed of the screw or the vibration frequency of the vibrating feeder, the required amount of refractory materials can be continuously and stably fed into the subsequent throwing mechanism.

2.2 Throwing Mechanism

The core of the throwing machine is the throwing mechanism. There are mainly two common types: mechanical throwing and pneumatic throwing.

2.2.1 Mechanical Throwing

In the mechanical throwing type, a high - speed rotating impeller or throwing arm is used. When the refractory materials enter the throwing area, they are accelerated by the high - speed rotating impeller or thrown out by the throwing arm. The speed and direction of the thrown materials can be adjusted by changing the rotation speed of the impeller or the angle and movement mode of the throwing arm. For example, some high - end mechanical throwing machines use variable - frequency motors to control the rotation speed of the impeller, which can achieve more accurate control of the throwing distance and material distribution.

2.2.2 Pneumatic Throwing

Pneumatic throwing machines utilize the high - pressure air flow to carry and throw the refractory materials. Compressed air is introduced into the material - containing chamber, and the refractory materials are entrained by the high - speed air flow and then ejected from the nozzle. The pressure and flow rate of the compressed air can be adjusted to control the throwing force and distance of the materials. This type of throwing machine has the advantages of simple structure, high throwing efficiency, and easy adjustment of the throwing parameters.

3. Advantages of the Converter Refractory Material Throwing Machine

3.1 High Efficiency

Compared with traditional manual or semi - manual methods of applying refractory materials, the throwing machine can significantly improve work efficiency. It can continuously and quickly throw a large amount of refractory materials, reducing the time required for refractory material application. For example, in a large - scale steelmaking plant, a high - performance throwing machine can complete the refractory material application task of a converter in a few hours, while manual operation may take several days, greatly improving the production rhythm of the steelmaking process.

3.2 Precise Material Distribution

The throwing machine can achieve precise control of the distribution of refractory materials. Through the adjustment of the throwing parameters such as the throwing angle, speed, and material feeding rate, the refractory materials can be evenly distributed on the inner wall of the converter according to the required thickness and shape. This ensures the uniform wear - resistance of the converter lining and effectively extends the service life of the converter. For instance, in the key areas of the converter that are prone to severe erosion, such as the slag - line area, more refractory materials can be accurately thrown to enhance the local wear - resistance.

3.3 Labor - Saving and Cost - Effective

Using a throwing machine can greatly reduce the labor intensity of workers. Workers only need to be responsible for operating the equipment, monitoring the process, and performing simple maintenance tasks, rather than engaging in heavy manual refractory material application work. At the same time, due to the high efficiency and precise material distribution of the throwing machine, the consumption of refractory materials can be optimized, reducing unnecessary waste of materials. In the long run, this can save a lot of labor costs and material costs for steelmaking enterprises.

4. Application Scenarios in Converter Steelmaking

4.1 New Converter Lining Construction

When building a new converter lining, the throwing machine is used to quickly and evenly apply a thick layer of refractory materials on the inner wall of the converter shell. This can ensure the initial construction quality of the lining, providing a good foundation for the subsequent long - term operation of the converter. The throwing machine can cooperate with other construction equipment to complete the construction of the converter lining in an orderly manner, shortening the construction period of the new converter.

4.2 Converter Lining Repair

During the operation of the converter, the lining will gradually be eroded due to high - temperature molten steel, slag, and chemical reactions. The throwing machine is an essential tool for lining repair. When local areas of the lining are damaged, the throwing machine can accurately throw refractory materials to the damaged areas for repair. In particular, for some areas that are difficult to access manually, the throwing machine can still complete the repair work efficiently, ensuring the continuous normal operation of the converter and minimizing production interruptions.

4.3 Slag - Line Protection in the Converter

The slag - line area of the converter is one of the areas most severely eroded by slag. The throwing machine can be used to strengthen the slag - line area by throwing special refractory materials with high corrosion resistance and wear - resistance. By increasing the thickness and quality of the refractory layer in the slag - line area, the service life of the converter in this key area can be effectively extended, reducing the frequency of converter maintenance and improving production efficiency.

5. Technological Development Trends of the Throwing Machine

5.1 Intelligent Control

With the development of intelligent technology, future throwing machines will be more intelligent. They will be equipped with advanced sensors to monitor various parameters during the material - throwing process in real - time, such as the amount of material thrown, the throwing speed, and the temperature of the working environment. Through intelligent control systems, the throwing machine can automatically adjust the working parameters according to the monitored data to ensure the best material - throwing effect. For example, if the sensor detects that the thickness of the refractory layer in a certain area is insufficient, the control system can automatically increase the material - feeding rate and throwing speed in this area.

5.2 Higher - Performance Materials Compatibility

As new types of refractory materials with better performance continue to emerge, the throwing machine needs to be able to adapt to these materials. Manufacturers will focus on developing throwing machines that can handle a wider range of refractory materials, including materials with special physical and chemical properties. This requires improvements in the material - feeding system and throwing mechanism of the throwing machine to ensure that different refractory materials can be smoothly fed and accurately thrown.

5.3 Energy - Saving and Emission - Reduction

In response to the global call for energy - saving and emission - reduction, the development of energy - saving throwing machines is an inevitable trend. New energy - saving technologies will be applied to the throwing machine, such as more efficient motors, optimized air - compression systems (for pneumatic throwing machines), and intelligent power - management systems. These technologies can reduce the energy consumption of the throwing machine during operation and also minimize the generation of waste gas and dust, making the steelmaking process more environmentally friendly.

6. Conclusion

The converter refractory material throwing machine is an important device in the steelmaking industry. Its application has brought great convenience and improvement to the application and maintenance of converter refractory materials. With the continuous development of technology, the throwing machine will continue to be optimized and upgraded in terms of efficiency, accuracy, intelligence, and environmental friendliness, playing an increasingly important role in promoting the high - quality development of the steelmaking industry.