Desulfurization Slag Raking Machine: A Critical Equipment for Efficient Desulfurization in Metallurgical Industry

In the metallurgical industry, especially in the iron and steel production process, desulfurization is a crucial step to ensure the quality of molten iron and subsequent steel products. Sulfur in molten iron will cause serious defects such as "hot brittleness" in steel, reducing its toughness, ductility and fatigue resistance. The desulfurization slag raking machine, as the core equipment to separate desulfurization slag from molten iron after desulfurization reaction, directly affects the desulfurization efficiency, molten iron recovery rate and production cost. This article will systematically elaborate on the structural characteristics, working principle, technical advantages, application scenarios and development trends of desulfurization slag raking machines.

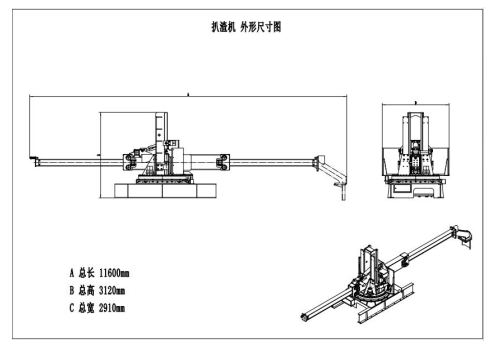

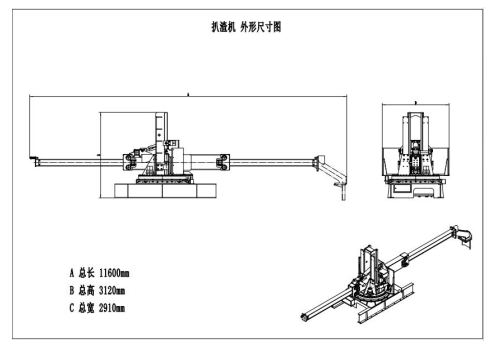

1. Structural Composition of Desulfurization Slag Raking Machine

The desulfurization slag raking machine is a integrated equipment combining mechanical structure, hydraulic system, electrical control system and thermal protection system. Its structural design is closely adapted to the harsh working environment of high temperature, dust and heavy load in the metallurgical site. The main components include the following parts:

1.1 Mechanical Execution System

The mechanical execution system is the core part of the slag raking machine, responsible for completing the key actions such as extending into the molten iron tank, raking slag, lifting and turning over. It mainly consists of a slag raking arm, a rake head, a slewing mechanism and a lifting mechanism. The slag raking arm is usually made of high-strength heat-resistant alloy steel, which has good high-temperature resistance and bending resistance to withstand the high temperature radiation of molten iron (up to 1300-1500℃) and the impact of slag. The rake head is designed with a special tooth shape, which can effectively hook and scrape the desulfurization slag floating on the surface of molten iron without carrying too much molten iron. The slewing mechanism and lifting mechanism adopt a combination of hydraulic cylinder and gear transmission, which can realize the multi-angle and stable movement of the slag raking arm.

1.2 Hydraulic Drive System

The hydraulic drive system provides power for the mechanical execution system, and its performance directly determines the operation stability and response speed of the slag raking machine. It is composed of hydraulic pump, hydraulic cylinder, control valve group, oil tank and cooling system. The hydraulic pump adopts variable displacement piston pump, which can adjust the oil supply according to the load demand, realizing energy saving and high efficiency. The control valve group uses electro-hydraulic proportional valves to precisely control the speed and position of the hydraulic cylinder, ensuring the smoothness of the slag raking action. The cooling system adopts air-cooled or water-cooled mode to control the temperature of the hydraulic oil within the normal working range (generally 30-55℃), preventing the oil from deteriorating and affecting the system performance.

1.3 Electrical Control System

The electrical control system is the "brain" of the desulfurization slag raking machine, responsible for coordinating the work of each system and realizing automatic control. It mainly includes PLC (Programmable Logic Controller), touch screen, sensor, frequency converter and emergency stop device. The PLC uses high-reliability industrial-grade products, which can process multiple input and output signals in real time, and control the action sequence of the hydraulic system and mechanical system according to the preset program. The touch screen provides a human-machine interaction interface, through which operators can set parameters (such as slag raking speed, arm extension length), monitor the working status of the equipment (such as oil temperature, pressure, arm position) and view fault information. Sensors (such as position sensors, pressure sensors, temperature sensors) realize real-time detection of key parameters and feed back to the PLC to form a closed-loop control. The emergency stop device can quickly cut off the power and oil circuit in case of emergency, ensuring the safety of personnel and equipment.

1.4 Thermal Protection System

Considering the high-temperature working environment, the desulfurization slag raking machine is equipped with a complete thermal protection system. On the one hand, the key components such as the slag raking arm and rake head are coated with high-temperature resistant ceramic coating or equipped with water-cooling jackets to reduce the damage of high-temperature radiation. On the other hand, the electrical components and hydraulic pipelines near the high-temperature area are protected by heat insulation covers, and the cables use high-temperature resistant wires to prevent insulation aging. In addition, the equipment is also equipped with a temperature monitoring alarm device. When the temperature of key parts exceeds the set threshold, it will automatically alarm and remind the operator to take measures.

2. Working Principle of Desulfurization Slag Raking Machine

The working process of the desulfurization slag raking machine is closely connected with the desulfurization process of molten iron. Taking the molten iron pretreatment desulfurization process as an example, its working principle can be divided into the following steps:

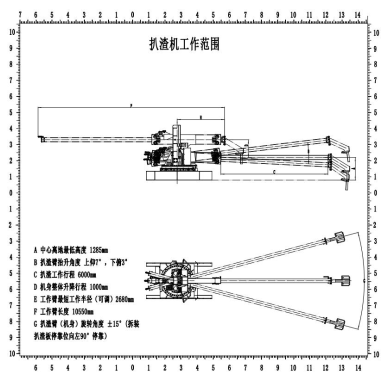

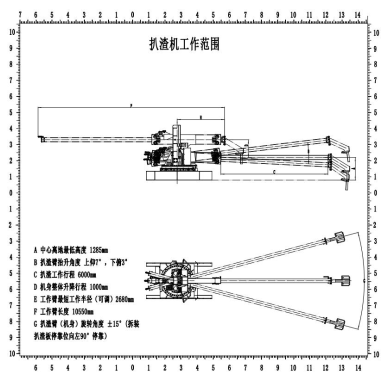

Preparation Stage: After the desulfurization agent (such as calcium carbide, magnesium powder) is injected into the molten iron tank and fully reacts with the sulfur in the molten iron, the desulfurization slag is formed and floats on the surface of the molten iron. At this time, the operator moves the desulfurization slag raking machine to the designated position through the traveling mechanism (some models are fixed, and the molten iron tank is moved to the working position), and adjusts the posture of the slag raking arm through the control system to align it with the molten iron tank.

Slag Raking Stage: The PLC sends a signal to the hydraulic system, and the lifting mechanism drives the slag raking arm to descend, so that the rake head extends into the molten iron tank and inserts into the desulfurization slag layer. Then, under the drive of the slewing mechanism, the slag raking arm swings horizontally, and the rake teeth hook the desulfurization slag and push it to one side of the molten iron tank. During this process, the position sensor and pressure sensor monitor the position of the rake head and the resistance of slag raking in real time. If the resistance is too large (such as encountering hard slag agglomeration), the system will automatically adjust the speed of the slag raking arm or lift the arm slightly to avoid equipment damage.

Slag Discharging Stage: After the desulfurization slag in the molten iron tank is raked to the designated position, the lifting mechanism drives the slag raking arm to rise, and the slewing mechanism rotates the arm to the upper part of the slag bin. Then, the turning mechanism drives the rake head to turn over, and the desulfurization slag falls into the slag bin under the action of gravity. After slag discharging, the slag raking arm resets to prepare for the next slag raking cycle.

Post-processing Stage: After the slag raking work is completed, the operator cleans the rake head and slag raking arm to remove the residual slag, and checks the working status of the hydraulic system, electrical system and thermal protection system. If any fault is found, it shall be handled in time to ensure the normal operation of the equipment in the next work.

3. Technical Advantages of Desulfurization Slag Raking Machine

Compared with the traditional manual slag raking or simple mechanical slag raking methods, the modern desulfurization slag raking machine has significant technical advantages, which are mainly reflected in the following aspects:

3.1 High Desulfurization Efficiency and Molten Iron Recovery Rate

The desulfurization slag raking machine adopts a precision control system and a special-shaped rake head design, which can accurately separate the desulfurization slag from the molten iron. The rake teeth are designed with a reasonable angle and spacing, which can effectively scrape the slag without carrying a large amount of molten iron. The test data shows that the molten iron loss rate of the automatic desulfurization slag raking machine is less than 1%, while the manual slag raking loss rate is as high as 3-5%. At the same time, the thorough slag raking can avoid the secondary reaction between the residual desulfurization slag and the molten iron, ensuring the desulfurization effect. The sulfur content of the molten iron after slag raking can be stably controlled below 0.005%, meeting the requirements of high-quality steel production.

3.2 High Automation and Labor Intensity Reduction

The desulfurization slag raking machine realizes full-process automatic control through the PLC and sensor system. The operator only needs to set the relevant parameters on the touch screen and start the automatic program, and the equipment can complete the actions of slag raking, slag discharging and resetting by itself. This not only reduces the labor intensity of the operators (avoiding long-term work in high-temperature, dusty environment), but also reduces the influence of human factors on the slag raking effect. For example, in the continuous production process of a large iron and steel plant, one operator can monitor 2-3 slag raking machines at the same time, which greatly improves the labor efficiency.

3.3 Good Stability and Long Service Life

The key components of the desulfurization slag raking machine are made of high-strength, high-temperature resistant materials, and the hydraulic system and electrical system adopt mature and reliable components. At the same time, the equipment is equipped with perfect fault diagnosis and protection functions, which can timely detect and handle faults such as oil leakage, overheating and overload, avoiding major equipment damage. Under normal maintenance conditions, the service life of the desulfurization slag raking machine can reach 8-10 years, and the average fault-free working time is more than 5000 hours, which meets the requirements of continuous production in the metallurgical industry.

3.4 Strong Adaptability

The desulfurization slag raking machine can be customized according to the specifications of the molten iron tank (such as volume, diameter), the type of desulfurization slag (such as viscosity, hardness) and the production process requirements. For example, for the molten iron tank with large volume (more than 300 tons), a slag raking machine with a longer and thicker slag raking arm can be designed; for the desulfurization slag with high viscosity, a rake head with larger tooth spacing and higher strength can be adopted. In addition, the equipment can also be adapted to different desulfurization processes (such as top injection desulfurization, bottom blowing desulfurization), showing strong versatility.

4. Application Scenarios of Desulfurization Slag Raking Machine

The desulfurization slag raking machine is mainly used in the desulfurization process of molten iron in the metallurgical industry, and its specific application scenarios include the following aspects:

4.1 Iron and Steel Plants

In large iron and steel plants, the desulfurization slag raking machine is an essential equipment in the molten iron pretreatment workshop. It is used to treat the desulfurization slag generated after the desulfurization of molten iron from the blast furnace, providing high-quality molten iron for the converter or electric furnace smelting. For example, in the production line of automotive sheet steel, the requirements for sulfur content in molten iron are extremely high, and the desulfurization slag raking machine can ensure that the sulfur content is controlled within the required range, improving the quality of the final product.

4.2 Foundries

In foundries that produce cast iron parts (such as engine blocks, pipe fittings), the desulfurization of molten iron is also an important process to improve the quality of castings. The desulfurization slag raking machine is used to remove the desulfurization slag in the molten iron, avoiding the formation of slag inclusions in the castings, and improving the density and mechanical properties of the castings. Compared with iron and steel plants, foundries usually use small and medium-sized slag raking machines to adapt to the production of small batches and multiple varieties.

4.3 Other Metallurgical Fields

In addition to iron and steel production and casting, the desulfurization slag raking machine is also used in other metallurgical fields that require desulfurization, such as the production of ferroalloys (such as ferromanganese, ferrochrome) and non-ferrous metals (such as copper, nickel). In these fields, the desulfurization slag raking machine is used to treat the desulfurization slag in the molten metal, ensuring the quality of the alloy or non-ferrous metal products.

5. Development Trends of Desulfurization Slag Raking Machine

With the continuous development of the metallurgical industry towards high efficiency, energy saving, intelligence and environmental protection, the desulfurization slag raking machine is also facing new development trends. The main development directions in the future are as follows:

5.1 Intelligence Upgrade

Intelligence is the most important development trend of desulfurization slag raking machines. In the future, the equipment will integrate technologies such as machine vision, artificial intelligence and big data to realize more precise and autonomous control. For example, the machine vision system can identify the thickness and distribution of the desulfurization slag layer in real time, and the AI algorithm can automatically adjust the slag raking parameters (such as rake head depth, swing speed) according to the slag condition, realizing adaptive slag raking. At the same time, through the big data analysis of the equipment's working status and production data, the predictive maintenance of the equipment can be realized, and the fault can be predicted in advance to reduce the maintenance time and cost.

5.2 Energy Saving and Environmental Protection

Under the background of global carbon reduction, energy saving and environmental protection have become important requirements for industrial equipment. The future desulfurization slag raking machine will adopt more energy-saving components and designs, such as using permanent magnet synchronous motors instead of traditional asynchronous motors to improve the efficiency of the power system; optimizing the hydraulic system to reduce energy loss. In terms of environmental protection, the equipment will be equipped with a more efficient dust collection system to reduce the emission of dust during the slag raking process. At the same time, the desulfurization slag can be recycled through the cooperative operation with the slag treatment equipment, realizing the resource utilization of solid waste.

5.3 Modular and Integrated Design

Modular and integrated design can improve the flexibility and maintainability of the equipment. The future desulfurization slag raking machine will adopt a modular structure, and the mechanical execution system, hydraulic system and electrical control system will be designed as independent modules. When the equipment needs to be maintained or upgraded, only the corresponding modules need to be replaced, which shortens the maintenance time and reduces the maintenance cost. At the same time, the integration of the slag raking machine with the desulfurization agent injection equipment, molten iron temperature detection equipment and other equipment will form a complete molten iron pretreatment integrated system, improving the overall production efficiency.

5.4 High-temperature Resistance and Corrosion Resistance Enhancement

With the increase of molten iron temperature and the use of new desulfurization agents, the working environment of the desulfurization slag raking machine is becoming more and more harsh. The future equipment will use new high-temperature resistant and corrosion-resistant materials, such as ceramic matrix composites, to improve the high-temperature resistance and corrosion resistance of the slag raking arm and rake head. At the same time, the thermal protection system will be optimized, such as adopting active cooling technology (such as air film cooling) to further reduce the impact of high-temperature radiation on the equipment.

6. Conclusion

As a key equipment in the molten iron desulfurization process, the desulfurization slag raking machine plays a vital role in improving the quality of metallurgical products, reducing production costs and ensuring production safety. Its structural design is increasingly perfect, and its working principle is continuously optimized, showing the technical advantages of high efficiency, automation and strong adaptability. With the development of the metallurgical industry towards intelligence and environmental protection, the desulfurization slag raking machine will also move towards the direction of intelligence upgrade, energy saving and environmental protection, modular design and material enhancement. In the future, it will better adapt to the harsh working environment and high-quality production requirements, and make greater contributions to the sustainable development of the metallurgical industry.