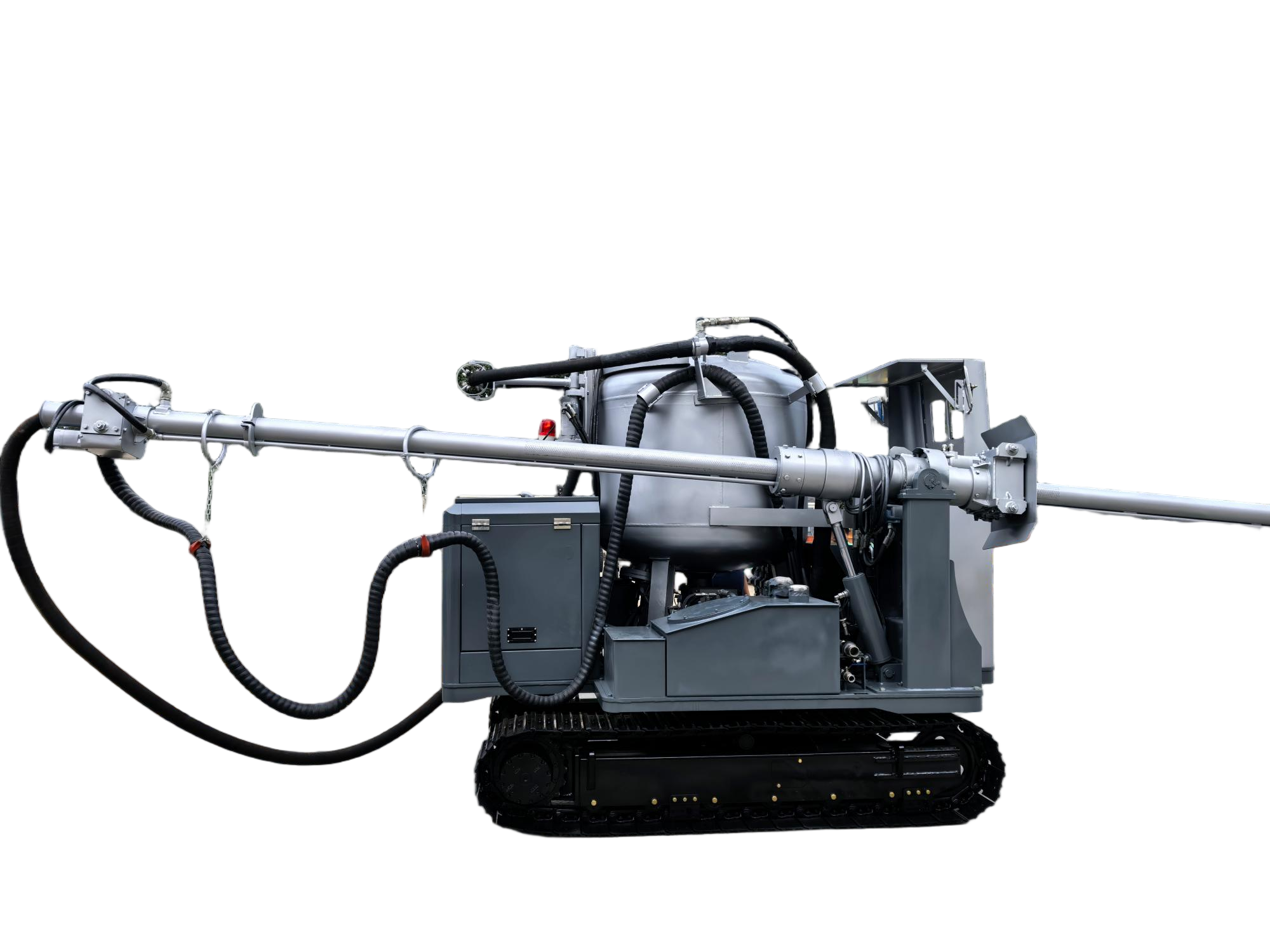

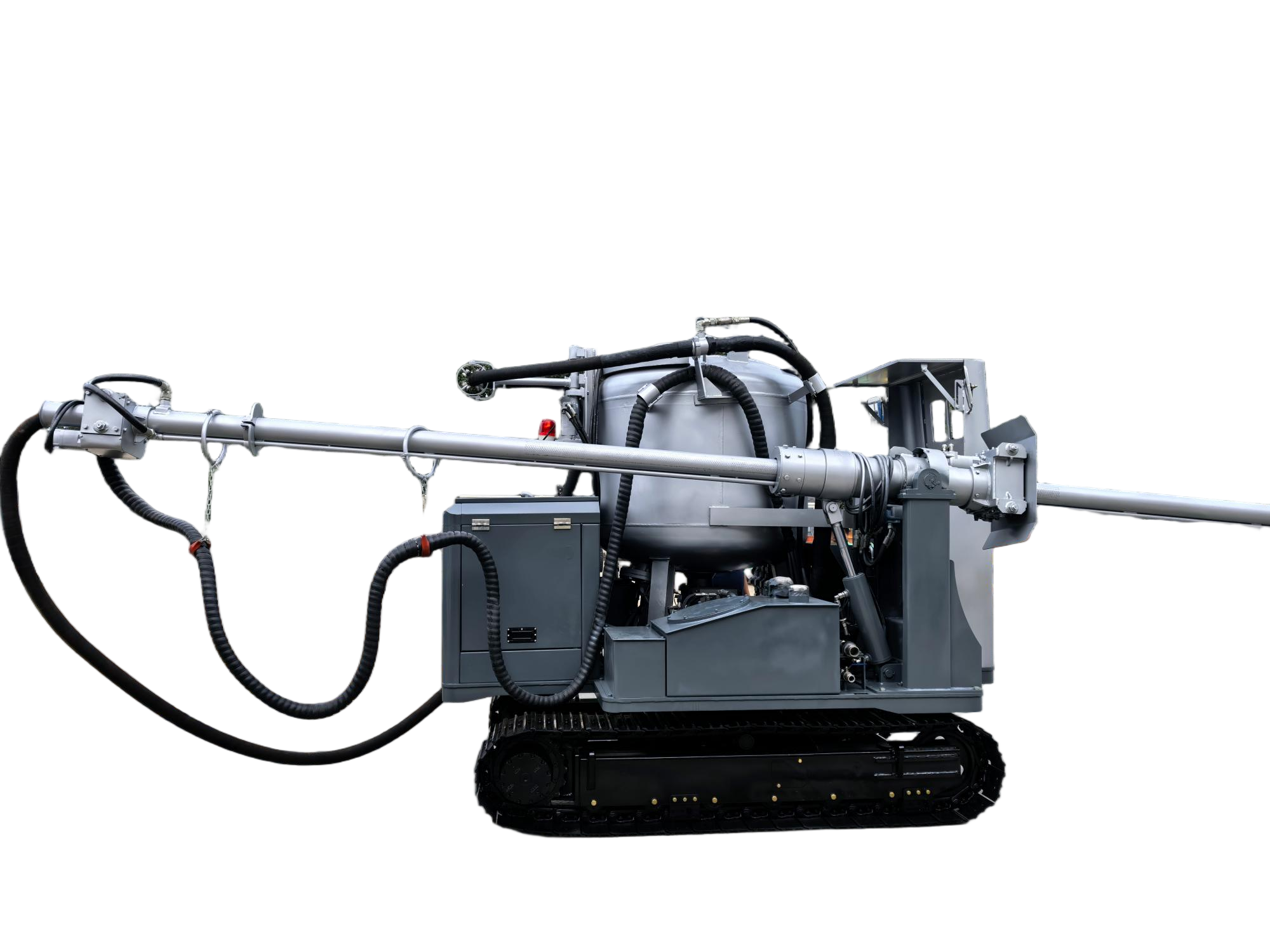

Semi-Dry Converter Gunning Machine: The Core Equipment for Efficient Converter Maintenance

In iron and steel metallurgical production, the converter, as the core equipment for steelmaking, operates under harsh conditions of high temperature, strong corrosion, and intense scouring for a long time. As a result, the furnace lining is prone to damages such as spalling, erosion, and cracking. The integrity of the furnace lining directly affects the steelmaking efficiency, molten steel quality, and service life of the converter. Therefore, timely and efficient furnace lining repair is crucial. The semi-dry converter gunning machine, a specialized equipment designed for converter lining repair, has become a key device to ensure the continuous and stable operation of the converter, thanks to its unique semi-dry gunning process, stable gunning material conveying capacity, and structural design adapted to converter operations. This article will comprehensively introduce the characteristics and value of this converter gunning machine, focusing on its core parameters: semi-dry gunning method, gunning material conveying rate of 60-100kg/min, and equipment weight of 6400kg.

I. Core Parameters and Design Orientation of the Equipment

The core parameters of this semi-dry converter gunning machine are accurately matched to the actual needs of converter lining repair, with targeted optimizations in terms of process, efficiency, and equipment stability. The specific parameters and design orientation are as follows:

(I) Analysis of Core Parameters

Gunning Method: Semi-Dry

The semi-dry gunning is an advanced process between dry and wet gunning. Its principle is to briefly mix dry gunning materials with a fixed amount of atomized water at the front end of the injection pipeline (or in the mixing chamber) to form a "semi-dry and semi-wet" paste-like material, which is then injected at high speed onto the damaged surface of the converter lining. This process not only avoids the defects of dry gunning, such as high dust emission and low material bonding strength, but also solves the problems of wet gunning, such as easy agglomeration of slurry and complex equipment cleaning. It balances environmental protection, repair quality, and operational convenience, making it the mainstream process choice for current converter lining repair.

Gunning Material Conveying Rate: 60-100kg/min

The gunning material conveying rate directly determines the repair efficiency of the converter lining. The conveying rate range of 60-100kg/min of this equipment can be flexibly adjusted according to the damaged area and damage degree of the converter lining:

For small-area local erosion, the conveying rate can be reduced to 60-70kg/min to achieve precise repair and avoid material waste.

For large-area spalling (such as in the converter molten pool and furnace mouth area), the rate can be increased to 80-100kg/min to quickly form a dense repair layer and significantly shorten the converter shutdown maintenance time.

Taking a 120-ton converter as an example, if the damaged area of the furnace lining is approximately 15㎡, using a conveying rate of 100kg/min with high-alumina gunning materials, the repair can be completed in only 40-50 minutes. This is more than 40% more efficient than traditional dry gunning machines, effectively ensuring the continuity of iron and steel production.

Equipment Weight: 6400kg

The equipment weight of 6400kg is the result of a structural design based on converter operation scenarios:

On one hand, the main body of the equipment is welded with high-strength steel plates, and the weight is concentrated on the feeding system and air supply system, ensuring that the equipment has no vibration or displacement during high-pressure injection operations and guaranteeing gunning accuracy.

On the other hand, the equipment is easy to move flexibly in the converter workshop and can adapt to the repair needs of converters of different tonnages (80-300 tons) without the need for separate customization for specific converters, reducing the equipment investment cost for enterprises.

(II) Design Orientation

The design orientation of this semi-dry converter gunning machine is "a professional converter lining repair equipment with high efficiency adaptation, stability, and reliability", and its core goal is to solve the pain points of "low efficiency, poor quality, and high pollution" in converter lining repair. The overall structure of the equipment is compact, and it can be directly parked beside the converter operation platform for operation without occupying too much workshop space. At the same time, the equipment has a high degree of integration, integrating the four systems of feeding, mixing, injection, and control into an integrated design, which reduces external pipeline connections, lowers the failure rate, and meets the production requirements of "high rhythm and high reliability" in the converter workshop.

II. Working Principle and Core Structure

II. Working Principle and Core Structure

(I) Working Principle

Based on the semi-dry gunning process, the working process of the equipment can be divided into four key stages of "material-water-air" synergy, ensuring that the gunning material is efficiently conveyed, uniformly mixed, and firmly attached to the surface of the converter lining:

Quantitative Conveying of Gunning Material: The pre-prepared special gunning material for the converter is loaded into a closed hopper. The double-screw conveyor at the bottom of the hopper accurately conveys the gunning material to the mixing chamber, avoiding the problem of "bridging" and blockage in the hopper (the inner wall of the hopper is equipped with an anti-adhesive coating).

High-Pressure Airflow Acceleration and Injection: The mixed semi-dry material is conveyed to the injection pipeline and injected onto the damaged surface of the converter lining through a 360° rotatable injection gun head (the length of the gun head is 1.2m, adapted to the diameter of the converter mouth).

Dense Bonding of the Repair Layer: When the high-speed injected semi-dry material particles come into contact with the high-temperature furnace lining (surface temperature: 800-1200℃), the moisture in the particles evaporates rapidly. At the same time, the material particles undergo plastic deformation under the action of impact force and form mechanical interlocking with the furnace lining matrix. In addition, the binder in the gunning material undergoes a chemical reaction at high temperature, further improving the bonding strength between the repair layer and the furnace lining, ensuring that the repair layer can withstand molten steel scouring and temperature fluctuations during the converter steelmaking process.

(II) Core Structure

The core structure of the equipment is designed around the three functions of "stable conveying, precise mixing, and efficient injection". Key components are made of wear-resistant and high-temperature-resistant materials to ensure the long-term stable operation of the equipment.

III. Performance Advantages and Application Scenarios

(I) Performance Advantages

Compared with traditional converter gunning equipment (such as dry gunning machines and wet gunning machines), this semi-dry converter gunning machine has significant advantages in repair quality, efficiency, environmental protection, and economy:

Better Repair Quality

The repair layer formed by the semi-dry process has high density (bulk density ≥2.6g/cm³), low porosity (≤15%), and high bonding strength with the furnace lining. It can withstand high temperatures above 1600℃, molten steel scouring (flow rate ≥1.5m/s), and furnace gas corrosion during converter steelmaking, effectively extending the service life of the converter lining. Practical data shows that the average furnace repair cycle of the converter lining repaired by this equipment can be extended from the original 15 days to 25 days, and the total service life of the converter lining is increased by more than 30%, which reduces the number of lining replacements and lowers the consumption cost of refractory materials.

Higher Repair Efficiency

The gunning material conveying rate of 60-100kg/min, combined with the integrated structural design, significantly shortens the converter shutdown maintenance time. Taking a 200-ton converter as an example, the traditional dry gunning machine takes 1.5-2 hours to repair the same damaged area, while this equipment only takes 40-60 minutes, reducing the shutdown time by more than 50%. It can reduce the production loss caused by converter maintenance by approximately 2-3 million yuan per year (calculated based on a profit of 500 yuan per ton of steel).

Better Environmental Performance

In the semi-dry process, the gunning material is pre-mixed with atomized water, and the dust emission during injection is ≤10mg/m³, which is much lower than the 50-80mg/m³ of dry gunning machines, meeting the requirements of the national Emission Standard of Air Pollutants for Iron and Steel Industry (GB 28664-2012). At the same time, the equipment has no slurry wastewater discharge, and only needs to clean the pipeline with compressed air after operation, resulting in low environmental pressure and reducing the enterprise's environmental governance cost.

More Convenient Operation and Maintenance

The equipment has a moderate weight and is equipped with mobile casters, making it easy to move in the workshop. The control system has a high degree of automation, and operators can work independently after 1-2 weeks of training. Core components (such as screw blades and injection gun heads) can be quickly disassembled and replaced, with short maintenance time (single maintenance ≤2 hours), and the comprehensive operation rate of the equipment is ≥95%, ensuring the converter maintenance needs.

(II) Application Scenarios

This semi-dry converter gunning machine is specially designed for converter lining repair and is suitable for various repair scenarios of converters of different tonnages in iron and steel enterprises. It has significant advantages especially in the following situations:

Daily Maintenance and Furnace Repair of Converters

After every 10-15 heats of steelmaking in the converter, slight erosion or small-area spalling may occur on the surface of the furnace lining (such as local damage after cleaning the slag at the furnace mouth). At this time, this equipment is used for daily furnace repair, and magnesium-carbon gunning materials are injected at a conveying rate of 60-70kg/min, which can timely repair minor damages, prevent the expansion of damages, and extend the converter overhaul cycle.

Mid-Term Repair of Converters

After the converter operates for 3-6 months, large-area erosion (depth: 50-100mm) may occur on the furnace lining (especially near the molten pool and tap hole). At this time, shutdown is required for mid-term repair. By using a conveying rate of 80-100kg/min and high-alumina-magnesium gunning materials, the eroded area is quickly filled, and a repair layer with a thickness of 80-120mm is formed to restore the thickness and structural integrity of the furnace lining, avoiding early overall replacement of the furnace lining.

Emergency Repair of Converters

If sudden spalling of the furnace lining occurs during converter steelmaking (such as local cracking and spalling caused by thermal shock), immediate shutdown and emergency repair are required to prevent safety accidents caused by molten steel leakage. This equipment can be quickly moved to the converter and perform emergency gunning at the maximum conveying rate of 100kg/min, completing the repair of the damaged area within 1 hour, resuming converter production as soon as possible, and reducing the loss caused by sudden shutdown.

V. Equipment Value and Industry Significance

With its core parameters accurately matching the converter repair needs, advanced semi-dry process, and stable and reliable performance, this semi-dry converter gunning machine brings significant economic value and industry significance to iron and steel enterprises:

From the perspective of economic value, by improving the repair efficiency of the converter lining and extending the service life of the lining, the equipment directly reduces the enterprise's refractory material consumption cost and production loss, resulting in remarkable economic benefits.

From the perspective of industry significance, the equipment promotes the upgrading of the converter lining repair process from "dry" to "semi-dry", reduces dust pollution in the gunning operation of the iron and steel industry, and conforms to the national "green iron and steel" development strategy. At the same time, the high automation and high adaptability of the equipment provide small and medium-sized iron and steel enterprises with an efficient and economical converter maintenance solution, which helps to improve the overall equipment maintenance level and production efficiency of the industry and promote the high-quality and sustainable development of the iron and steel industry.

II. Working Principle and Core Structure

II. Working Principle and Core Structure