Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

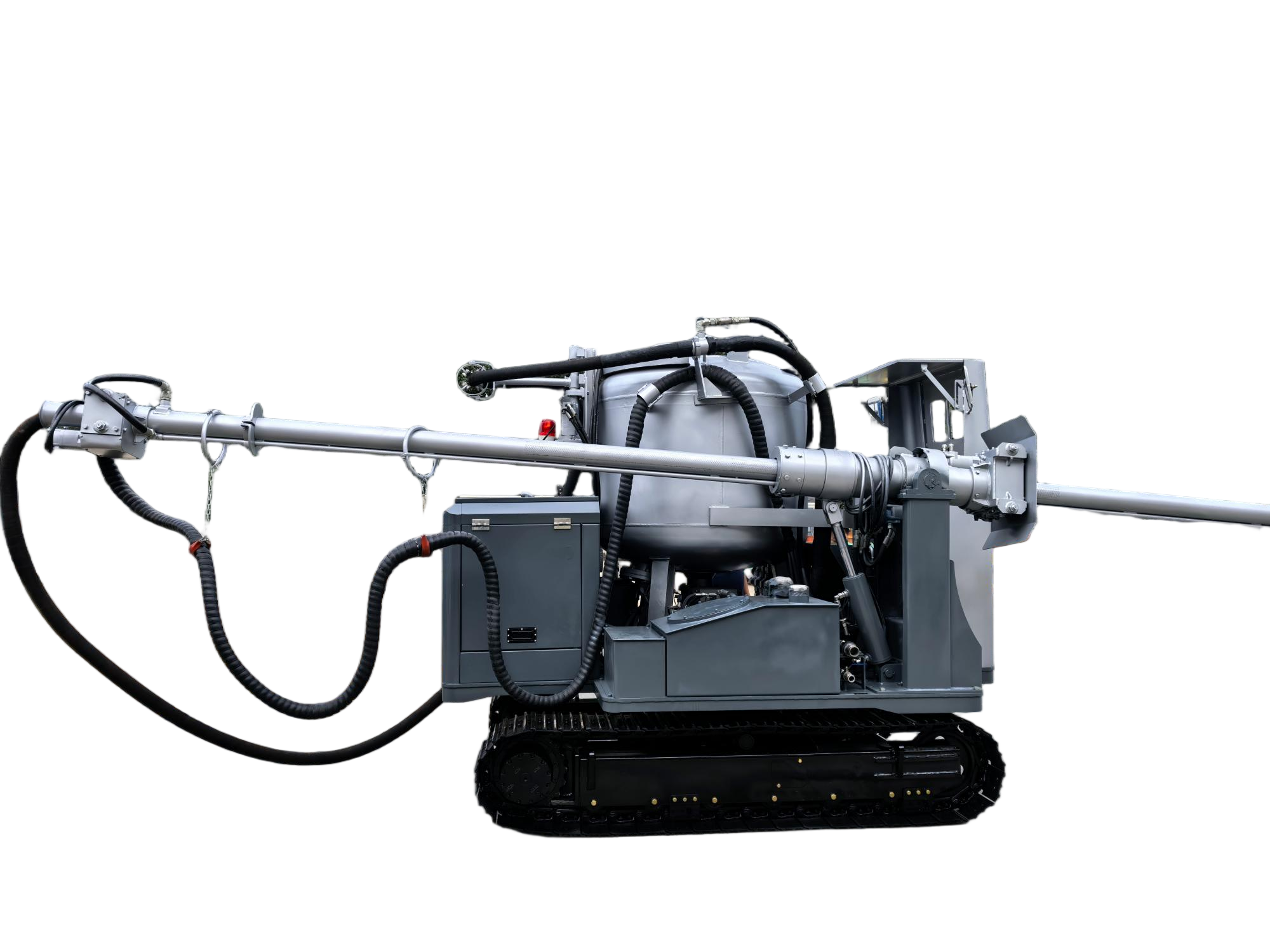

The fully automatic converter gunning machine enables more efficient repair

In the iron and steel smelting process, the converter serves as the core equipment for steelmaking. Its furnace lining refractory materials are exposed to harsh working conditions such as high temperatures, slag erosion, and mechanical impact for a long time, making them highly prone to problems like wear and spalling. If not repaired in a timely manner, this will not only shorten the service life of the converter but also may lead to safety accidents and affect the quality of molten steel. As a key piece of equipment specifically designed for repairing the refractory materials of converter linings, the converter refractory gunning machine, with its efficient, convenient, and reliable performance, has become an important support for modern iron and steel enterprises to ensure the continuous and stable production of converters.

Extending the service life of the converter lining: During the operation of the converter lining, it will experience local spalling and thinning due to the scouring and erosion of molten steel and slag. The gunning machine can spray specially-made refractory gunning materials onto the damaged areas at high pressure, forming a dense and solid new refractory layer to fill the damaged parts. This effectively prevents further intensification of erosion, significantly extends the overall service life of the lining, and reduces the frequency of lining replacement.

Ensuring continuous production of the converter: Traditional lining repair methods often require a long furnace shutdown time, which seriously affects the production rhythm. In contrast, the converter refractory gunning machine enables "on-line rapid repair" — it can operate during the interval between converter tapping or a short furnace shutdown, with the repair time usually only taking tens of minutes. This greatly shortens the shutdown duration, ensures the continuity of converter production, and improves equipment utilization.

Stabilizing molten steel quality and ensuring production safety: If the lining is severely damaged, it may cause direct contact between molten steel and the furnace shell, leading to abnormal molten steel composition (such as increased carbon and nitrogen content), and even safety accidents like furnace shell burnout. By promptly repairing the damaged lining, the gunning machine ensures the integrity and airtightness of the lining. This not only avoids fluctuations in molten steel quality but also eliminates potential safety hazards, providing a stable and safe environment for steelmaking production.

Efficient and stable spraying system: The equipment is equipped with a high-pressure spray pump and precise material conveying pipelines, which can spray refractory gunning materials (dry powder or wet materials) onto the damaged parts of the furnace lining at a uniform speed and pressure. The spray pressure can be flexibly adjusted according to the type of gunning material and the degree of damage, ensuring that the gunning material adheres tightly to the original lining without easy detachment. The formed gunning layer has high density and meets the required strength standards.

Convenient operation and high degree of automation: Most modern converter refractory gunning machines are equipped with a remote control system and a visual operation interface. Operators do not need to be in close proximity to the high-temperature converter; instead, they can complete operations such as positioning the gunning location, adjusting spray parameters, and starting/stopping the operation through the control console. Some high-end equipment also integrates a lining wear detection function, which can automatically identify damaged areas and plan gunning paths, reducing manual intervention and improving operation accuracy and efficiency.

Structural design adapted to harsh working conditions: The main components of the equipment (such as the spray gun, conveying pipelines, and power system) are made of special high-temperature and wear-resistant materials (e.g., stainless steel, wear-resistant alloys). These materials can withstand the high-temperature environment (150-300℃) around the converter and the frictional wear caused by gunning materials. At the same time, the equipment is equipped with a cooling system and a dust-proof sealing structure, which can effectively prevent high-temperature baking and dust intrusion, ensuring the long-term stable operation of the equipment under harsh working conditions.

Compatibility with multiple types of gunning materials: Different converter lining materials (e.g., magnesia-carbon bricks, alumina-magnesia bricks) and damage conditions have different requirements for gunning materials. The gunning machine is compatible with various types of gunning materials, including dry powder gunning materials, semi-dry gunning materials, and wet gunning materials. By simply adjusting the material conveying method and spray parameters, it can meet the repair needs in different scenarios, featuring strong versatility.

Significantly reducing production costs: On one hand, by extending the service life of the lining, the gunning machine reduces the replacement frequency of refractory bricks and procurement costs. On the other hand, on-line rapid repair shortens the shutdown time, improves the effective operation rate of the converter, and increases steel output. Statistics show that for converters using gunning machines, the service life of the lining can be extended by 30%-50%, and the annual production cost can be reduced by 10%-15%.

Better repair effect and higher reliability: Manual repair has problems such as uneven smearing and poor adhesion, resulting in easy detachment of the repair layer. In contrast, the gunning layer formed by the gunning machine through high-pressure spraying has high bonding strength with the original lining, with a density of over 90%. It can effectively resist slag erosion and mechanical impact, achieving a more stable repair effect. At the same time, automated operation avoids the randomness of manual operation, ensuring consistent repair quality each time and reducing production risks caused by improper repair.

Enhancing production safety and environmental friendliness: Traditional manual repair requires operators to work in the high-temperature area near the converter, posing high safety risks. The remote operation mode of the gunning machine completely solves this problem and ensures the safety of personnel. In addition, the equipment's sealed material conveying system can reduce the diffusion of gunning material dust. When combined with a dust collection device, it can effectively reduce dust pollution, meeting the environmental protection requirements of modern iron and steel enterprises.

Strong flexibility to adapt to different production rhythms: The production rhythm of converters is affected by factors such as steel grades and order requirements. The gunning machine can flexibly arrange repair operations according to the production plan — it can perform "rapid minor repairs" during the tapping interval or "local major repairs" during short furnace shutdowns in shifts, without disrupting the overall production rhythm. This makes it perfectly suitable for the dynamic production needs of converters.