Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

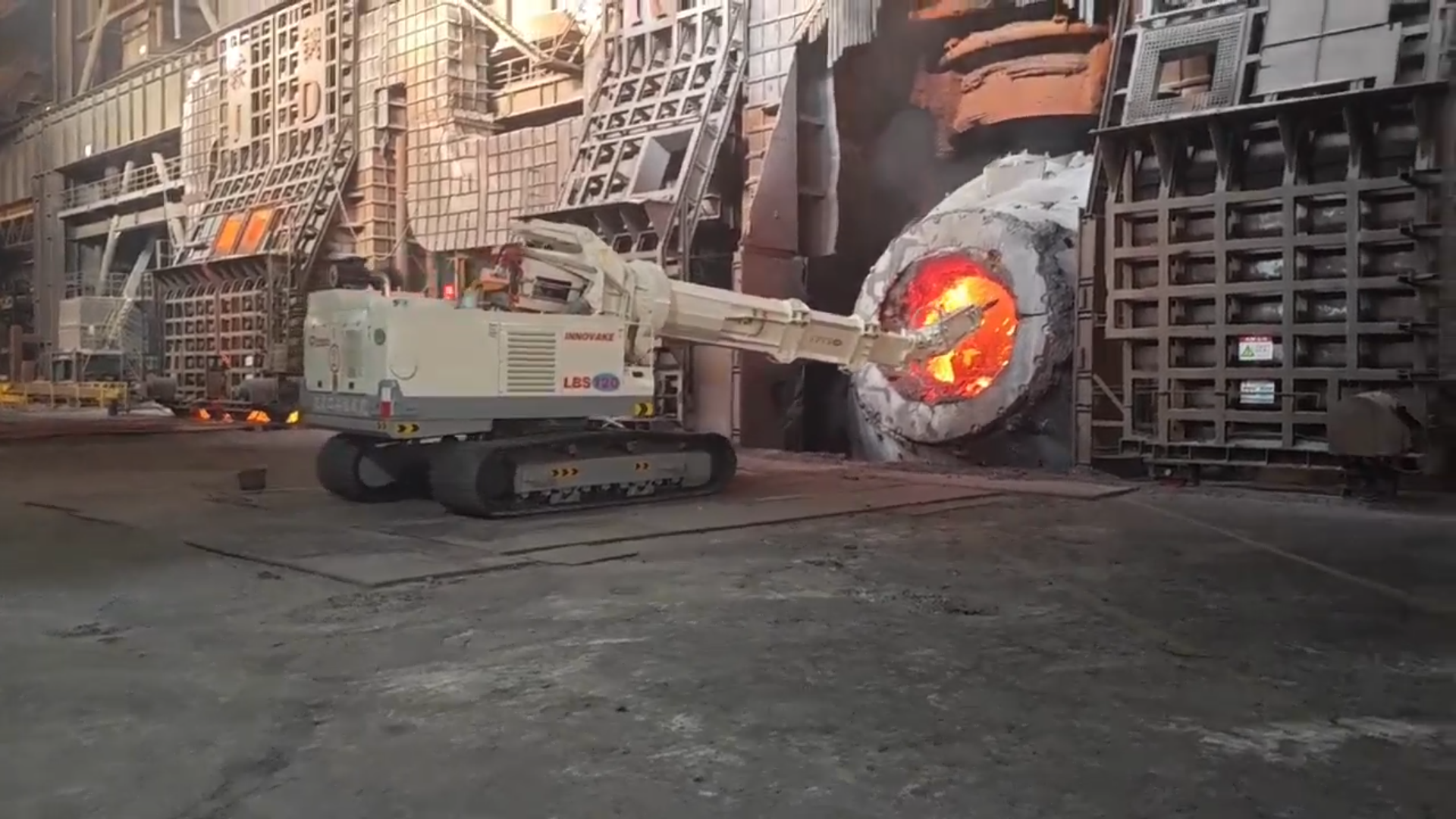

In the modern steelmaking industry, the converter stands as the core equipment for molten iron smelting, where high-temperature chemical reactions transform raw materials into qualified steel. However, during the long-term smelting process, molten slag and metal oxides inevitably adhere to the inner lining of the converter, forming a hard "brick deposit" layer. This layer not only reduces the effective volume of the converter, lowers smelting efficiency, but also poses potential safety hazards such as lining erosion and even converter leakage. Against this background, the Converter Debricking Machine emerges as a key equipment to solve this problem, playing an irreplaceable role in ensuring the stable operation of the steelmaking process.

Mechanical Execution System: It is the core part of the debricking machine, including the debricking hammer, lifting mechanism and traversing mechanism. The debricking hammer is usually made of high-strength alloy steel, which has strong wear resistance and impact resistance; the lifting mechanism and traversing mechanism drive the hammer to move in multiple directions (up and down, left and right, front and back), so as to cover the entire inner lining of the converter.

Hydraulic Control System: Provides power for the mechanical execution system, and controls the impact force, frequency and movement speed of the debricking hammer through hydraulic valves and oil cylinders. The hydraulic system has the characteristics of stable power output and adjustable parameters, which can adapt to different thicknesses and hardness of brick deposits.

Intelligent Control System: Composed of PLC controller, touch screen and sensor, it realizes automatic control and monitoring of debricking operations. The system can preset debricking parameters according to the converter model and brick deposit condition, and real-time monitor the working status of the equipment (such as hammer position, impact force, hydraulic oil temperature, etc.). When an abnormality occurs, it can automatically alarm and stop the machine to ensure operational safety.

Safety Protection System: Includes safety guards, emergency stop buttons, overload protectors and other components. The safety guard prevents splashing slag from harming operators; the overload protector avoids equipment damage caused by excessive impact force; the emergency stop button can quickly cut off the power supply in case of emergency to avoid accidents.

Preparation Stage: Before starting the debricking operation, the operator first checks the working status of the equipment (such as the integrity of the debricking hammer, the pressure of the hydraulic system, the normal operation of the control system, etc.), and cleans up the sundries around the converter to ensure a safe working environment. At the same time, according to the detection results of the brick deposit layer (such as thickness, distribution area, hardness), the debricking parameters (impact force, hammering frequency, movement path) are set in the control system.

Positioning Stage: The converter is tilted to a preset angle (usually 30°~60°) to expose the brick deposit area. The debricking machine moves to the working position through the traversing mechanism, and the lifting mechanism adjusts the height of the debricking hammer to align it with the brick deposit layer. The sensor in the control system real-time feeds back the position information of the hammer to ensure accurate positioning.

Debricking Stage: The hydraulic system drives the debricking hammer to reciprocate, and impacts the brick deposit layer with a preset impact force. While hammering, the traversing mechanism and lifting mechanism drive the hammer to move according to the preset path, so as to remove the brick deposit layer layer by layer. During the process, the control system monitors the impact force and hammering frequency in real time. If the brick deposit is too hard, the system will automatically increase the impact force or adjust the hammering frequency to avoid incomplete debricking; if the impact force exceeds the safety threshold, the system will automatically reduce the force to protect the converter lining.

Inspection Stage: After the debricking operation is completed, the operator uses the visual inspection or ultrasonic detection equipment to check the inner lining of the converter. If there is residual brick deposit, the local debricking operation is carried out by adjusting the parameters of the debricking machine until the inner lining meets the smelting requirements. Finally, the debricking machine is reset, and the waste slag is cleaned up to complete the entire debricking process.

Intelligent Upgrading: Integrate technologies such as machine vision and artificial intelligence to realize automatic detection of brick deposit layers. The machine vision system can automatically identify the thickness and distribution of brick deposits through cameras and image processing algorithms, and the AI system can automatically optimize debricking parameters according to historical data, realizing "detection-decision-execution" integrated intelligent operation.

High-Performance Material Application: Adopt new high-strength, wear-resistant materials (such as ceramic composite materials, high-speed steel) to manufacture debricking hammers, which can extend the service life of the hammer by 30%~50% and reduce the frequency of replacement parts.

Modular Design: Adopt modular design concept to divide the debricking machine into multiple independent modules (such as execution module, control module, safety module). This design not only facilitates the maintenance and replacement of equipment, but also can be customized according to the needs of different steel plants, improving the adaptability of the equipment.

Digital Management: Connect the debricking machine to the digital management platform of the steel plant, realize real-time monitoring and data analysis of the equipment working status, predict equipment failures in advance, and formulate scientific maintenance plans to improve the management level of the equipment.